Reduce friction simply means the lowering the resistance of the body. There are many different types of approaches and methods to reduce friction. Let us see those methods in details.

- By grinding the surfaces to a smooth finish.

- By making use of lubricants

- By streamlining the body

- By using electrostatic magnetic levitation to reduce contact between surfaces

- By using sliding friction instead of rolling friction

- By using fluid friction instead of dry friction

- By reducing the amount of pressure or weight applied on the body

- Frequently Asked Questions (FAQ’s)

First let us get some basic idea about the reduce friction.

Reduce friction:

The term “reduce friction” simply refers to “minimise the friction.”

A surface or an object experiencing friction is defined as the resistance they encounter as they are moved over another. This resistance created by the friction causes wear and tear between the surface which are in contact and hence it is necessary to reduce friction.

Now let us see various methods mentioned below of reduce friction in details along with its examples.

Different approaches and methods to reduce friction and their examples

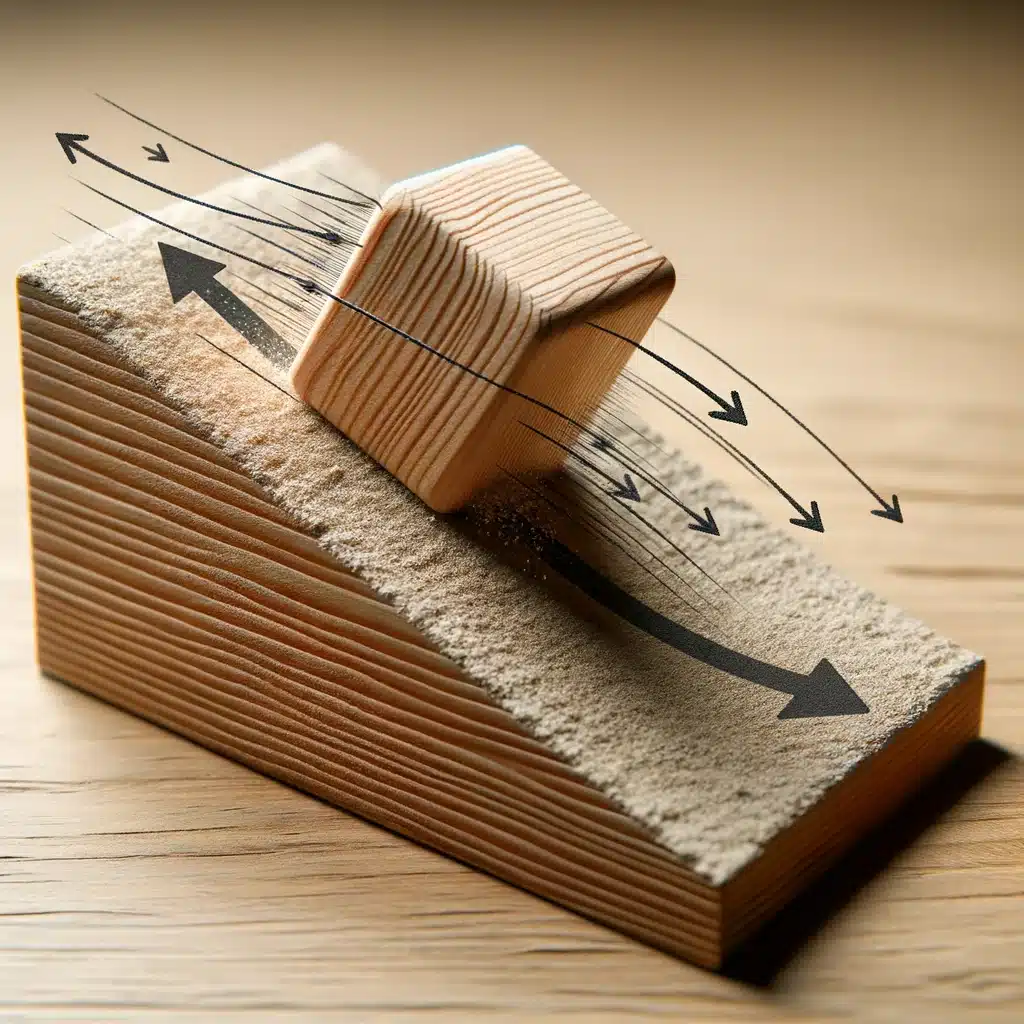

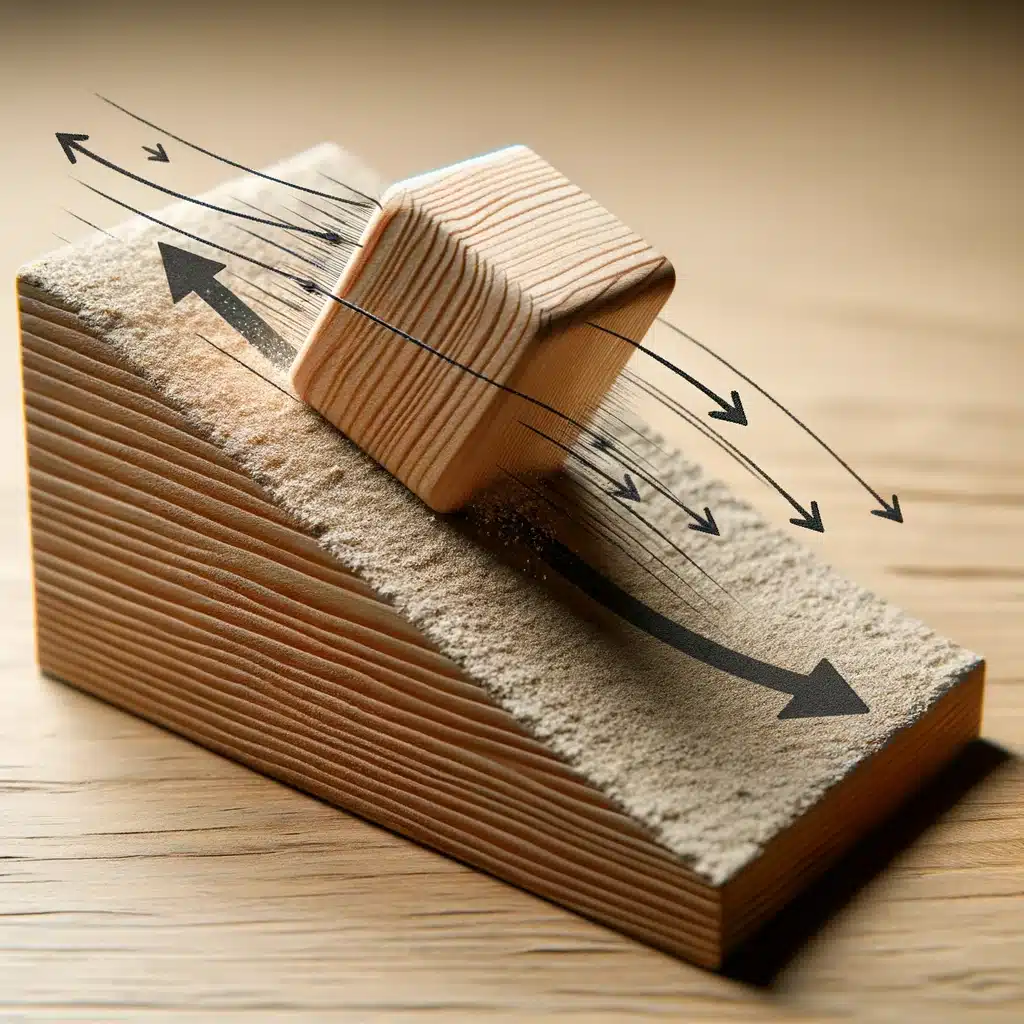

1.By grinding the surfaces to a smooth finish.

Friction is created when two surfaces slide over one other. In terms of friction, the sticking mechanism at the microscopic size is the most important component to consider. Making the sliding surfaces smoother will help to lessen the amount of sticking.

There are three types of methods to smooth the surfaces

- Grinding

- Using sand papers

- Chemical itching

Examples

- Polishing the wooden furniture and sculpture

- Removing corrosion with the help of chemicals

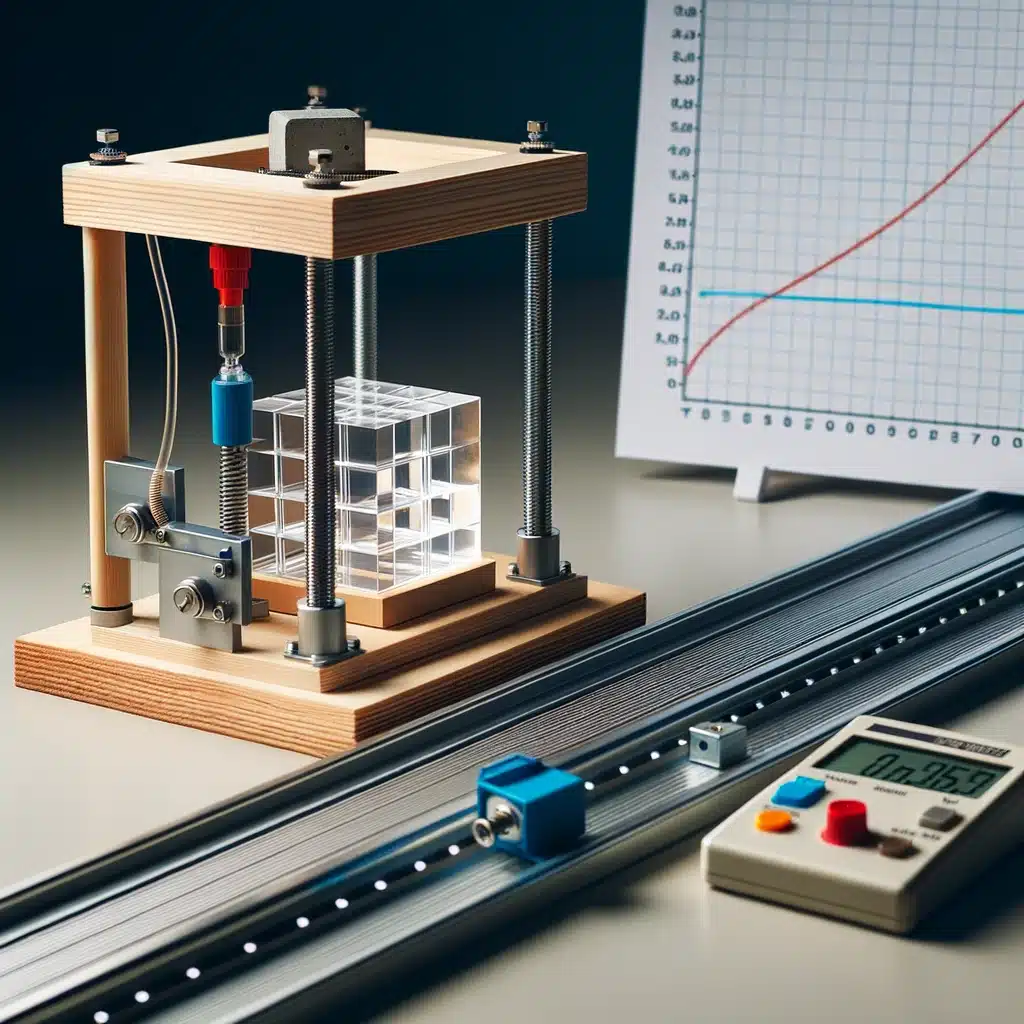

2.By making use of lubricants

Lubricants are chemicals that are applied to surfaces with the goal of reducing friction. It has the potential to minimise heat generation while also ensuring smooth sliding. Lubricants are usually semi-solid paste-like compounds that are used to minimise dry sliding friction by reducing frictional heat generation.

Examples

- Lubricants in the engine components of an automobile.

- The use of protective paints to keep metal from oxidising

- Oiling the door hinges will make them easier to open and close.

- Grease is used to keep bicycle parts moving smoothly.

Image Credits: Image by Dibyendu Joardar from Pixabay

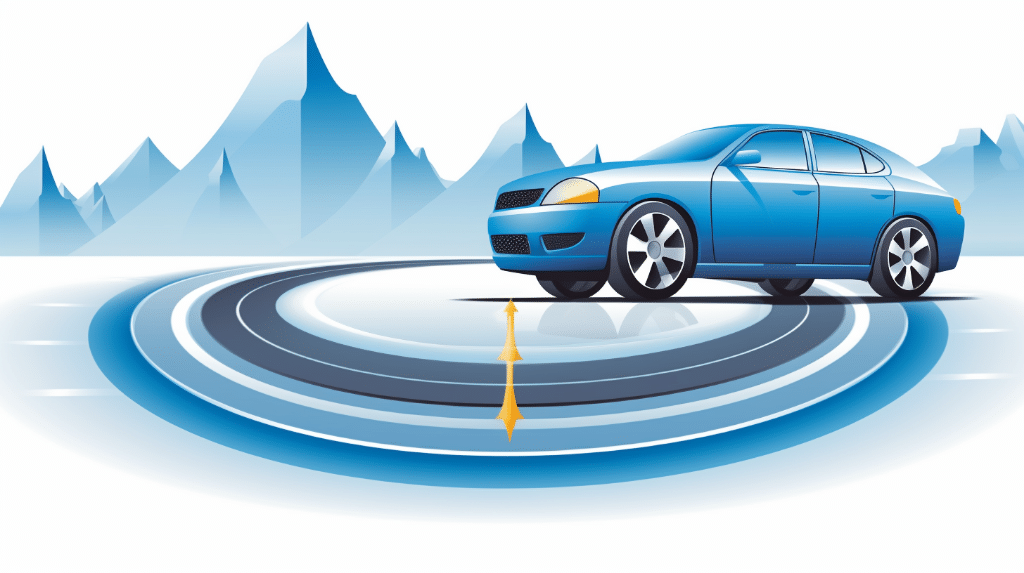

3.By streamlining the body

A streamlined body aids in the reduction of friction, which is especially important in fluids. It makes it possible for the sliding body to travel through the medium with the least amount of resistance.

Examples

- The streamlined bodies of fish and birds are copied in order to guarantee that there is as little friction as possible.

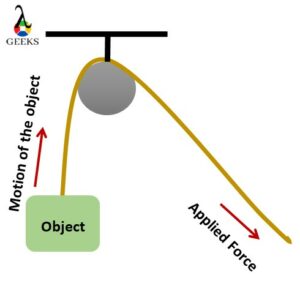

4. By using electrostatic magnetic levitation to reduce contact between surfaces

Friction can be reduced by reducing the amount of contact made during sliding. Through the use of magnetic levitation or charging both surfaces with the same polarity, we may significantly decrease touching.

Examples

- A maglev train operates on the idea of magnetic levitation, which reduces friction and allows for faster travel while also providing a more comfortable ride for passengers.

Image Credits: Lars Plougmann, The Shanghai Transrapid maglev train, CC BY-SA 2.0

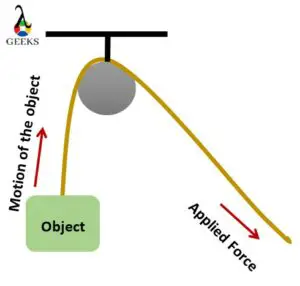

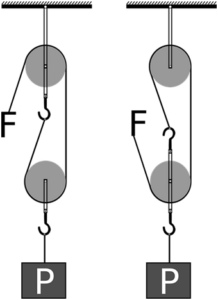

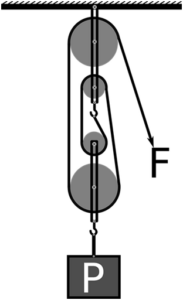

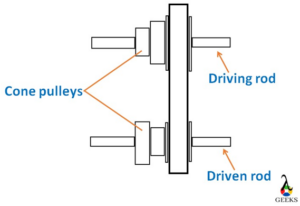

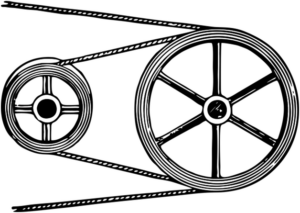

5.By using sliding friction instead of rolling friction

Sliding friction is always larger than rolling friction, regardless of the situation. Consider the possibility of an automobile with square wheels. Friction created by rolling is used extensively in our daily lives.

Read more about rolling friction

Examples

- Ball bearings are used to separate two bearing races by using balls as separators between the two races. The result is that sliding friction becomes rolling friction. The races will no longer glide over one another, but will instead pass the weight to the balls through rolling friction instead.

- Vehicle breaking mechanism

- Rubbing our own hands together

Read more about the examples of sliding friction.

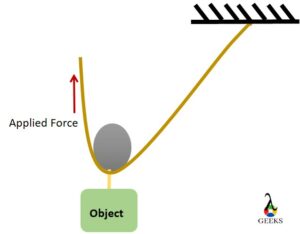

6.By using fluid friction instead of dry friction

When compared to solid surfaces, fluids have lower coefficients of friction. Because they are very resistive to motion, fluids having a high density have a high coefficient of fluid friction. As a result, aeroplanes can move at far higher speeds than automobiles. In addition, when we apply lubricants or oil to surfaces, we are effectively changing dry friction into fluid friction, which is beneficial.

Read more about the examples of dry friction.

Examples

- Diving into the water

- Walking on an oily surface

- Swimming of the fishes in water

Read more about the examples of fluid friction

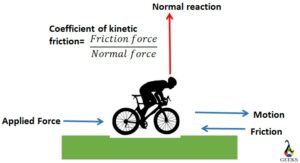

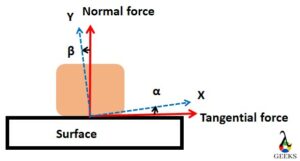

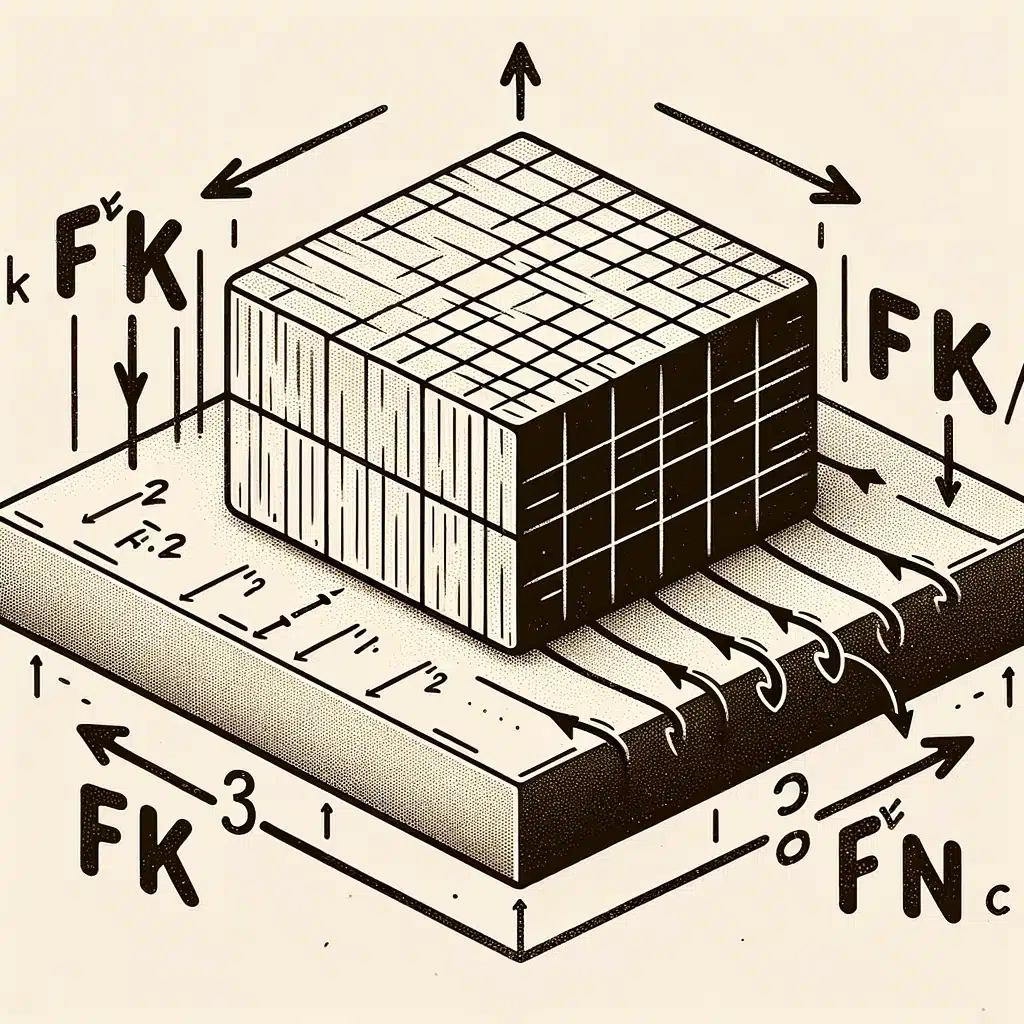

7. By reducing the amount of pressure or weight applied on the body

The amount of friction created is exactly proportional to the amount of normal force that is applied to the friction surface. The weight of the body acts as a normal force on the object due to the fact that we are on the surface of the planet. There will be very little or no friction in space. Selecting the right materials to decrease friction is so important.

Frequently Asked Questions (FAQ’s):

Q. What is reducing the friction?

Ans: Reduce friction simply means reducing resistance.

Smoothening of the surfaces which are in contact with each other to make them function easy and to avoid the production of frictional heat, is called the reduce friction.

Q. Why do we reduce friction

Ans: In some cases, it is necessary to make system work smoothly.

A necessary part friction is responsible for most of the wear and tear on working parts. Destroying the uniformity of the surfaces is one of its primary effects. Because of this, it is suggested that friction be reduced in specific circumstances.

Q. When would you want to decrease friction

Ans: It is sometimes essential to minimise friction in order to ensure safety from occurring.

The term “opposing force” refers to the fact that friction always acts in the opposite direction of a body that is moving or attempting to move. We aim at reducing friction where it is unnecessary. When machine parts are in contact with each other, friction reduces the efficiency of the machine; consequently, we oil them to minimise friction. Oil separates surfaces, which reduces friction between them.

Q. Reduce friction examples

Ans: Following is the list of examples of reduce friction

- Walking on the ground

- Cycling on the road

- Vehicles braking system

- Sanding

- Train wheels

- Trolley bag wheels

- Roller skating

- Lubricants in the hinges

- Flying bird

- Oiling the engines

- Powder on carrom board

Q. Why do we increase or reduce the friction

Ans: Friction is the vital thing in our daily life and surrounding.

A firmer grasp on the object is required in order to maintain control over its motions. For example, if there is no friction on the road, the car would slip and will never come to a complete stop; thus, roads are constructed using concrete to enhance the amount of friction. However, it is generally important to lessen the friction in order to ensure that the machines operate as smoothly as possible. Consequently, depending on the requirements of the system under consideration, it is necessary to either enhance or decrease friction.

Q. Can we reduce friction to zero

Ans: We will never be able to entirely remove friction since it is required for any motion.

Without friction, we would be unable to picture any motion because there is no motion on a smooth surface. A substantial quantity of lubricants, such as oil, water, and grease, can be used to minimise friction to a great extent but it is not possible to completely eliminate friction.

Q. Does sand reduce friction

Ans: As the concentration of sand particles in the lubricated sliding contact rises, the friction and wear rates in the sliding contact increase proportionally.

Q. Does lubricant increase or decrease friction

Ans: Regular lubrication with oil or grease is required to decrease friction between machine components.

Lubrication reduces the amount of heat generated when two moving surfaces come into contact. Because it forms a film between two surfaces, it makes the process smoother and more efficient by reducing friction and so improving performance and efficiency.

Q. How do lubricants reduce friction

Ans: The term “lubricant” can be described as a material, such as grease, that when applied as a layer between two solid surfaces, reduces friction, heat generation, and wear and tear.

Lubricants are often organic in nature, and it is added to minimise friction between surfaces that are in mutual contact, which in turn lessens the amount of heat created when the surfaces move. Lubricants can also perform other functions such as conveying foreign particles, transferring forces, and heating or cooling the surfaces they come into contact with, among others.

Q. Does water reduce friction

Ans: Water is typically effective in reducing friction between two surfaces. In order to reduce friction between two surfaces, water must act as a barrier between the two surfaces. It does this by separating them and reducing the contact area between them. It can only accomplish this if none of the surfaces is absorptive; otherwise, the water will not be able to stay between the two surfaces.

Q. How will you decrease friction on your floors

Ans: The simpler way to decrease or reduce friction on your floors is by polishing the surface of the floors. By polishing the surface of the floor, roughness gets decreased and resulting into smooth surface.

Q. Does graphite reduce friction

Ans: Friction is reduced to an extreme degree by the lamellar structure of graphite. To prevent direct contact between the metals and the development of adhesion and scuffing during the friction process, solid graphite lubricant can be applied over the surface of the counterpart.

Q. Do ball bearings reduce friction

Ans: Ball bearing is the best example of rolling friction.

Whenever the axle rotates, the steel balls and wheel revolve in the opposite direction of the axle’s rotation. As a result, the rolling friction between the two cylinders is lower than the sliding friction between them. Bearings that roll rather than slide minimise friction as a result of the rolling friction that they generate.

Sliding friction is turned into rolling friction as a result of the usage of rollers and wheels in production. Because rolling friction is less than sliding friction, we may lower the amount of force necessary to move an item by using rollers and wheels. As a result, the object can be moved more readily when using rollers and wheels.

Q. Is there friction in the desert

Ans: It is difficult to walk on the desert sand.

Our feet and sand particles have less friction when we step on sand. While walking on the sand, our feet become slippery due to the rolling. As a result, walking on sand is more difficult due to the reduced friction.

Q. Does powder reduce friction

Ans: Sliding friction is the friction come into play when we use powder on any surface.

When talcum powder is dry, it has a minor friction-reducing effect on some materials against the skin, but when it is wet, it has the opposite effect. Additionally, powder is highly suggested and should be placed on the surface of the carrom board to smooth up the surface. Due to this striker and other coins of the game can easily slide.

Q. Does ice reduce friction

Ans: Sliding on ice or snow is significantly less difficult than sliding on most other surfaces, and no one denies that fact. However, although liquid water at the ice surface reduces sliding friction on ice, the current opinion is that this liquid water is not dissolved by pressure, but rather by the frictional heat created during sliding.

Q. Does rain increase friction

Ans: When water is present in sufficient quantities, it works as a lubricant. The quantity of rain that falls and the amount of standing water on the pavement can both have an impact on this change in elevation. Heavy rains may frequently reduce the coefficient of friction to 0.4, which is about half of what it would be on a dry pavement under normal conditions.

Q. Does tire tread reduce friction

Ans: Tire tread is meant to channel water away from the wheel when roadways are moist.

In rainy weather, when the roads are slick from rain or snow, tyre tread is designed to channel extra water away from underneath the wheel. This enables for the greatest amount of contact between the road and your tyre when it is most needed. To minimise dangerous slippage on snow and ice, winter tyres are even designed to have more gaps in the treads than regular tyres.

Q. Does car brakes reduce friction

Ans: Most of the car brakes employ friction between two surfaces to convert kinetic energy into heat.

Car brakes operate because of friction; the brake pads push down on the rotors, which causes the friction to slow the wheels. Friction is what causes brakes to work. Because it determines how much power is used to drive the rotors and pads together, the brake pedal has the ability to alter the degree of friction.

Q. How do air cushions reduce friction

Ans: An air cushion may be created on any flat surface, whether it is on land or in water, by trapped air currents! It is possible to glide effortlessly over the smooth surface underneath because of the cushion’s significant reduction in frictional resistance.

Q. How does water affect the friction of sand

Ans: The addition of a little amount of water but not too much to sand significantly reduces sliding friction.

Small quantities of water can generate capillary bridges, according to most experts. The shear modulus of the sand is increased by the creation of capillary water bridges, which makes sliding easier. When the capillary bridges become clogged with too much water, the modulus decreases, causing the friction coefficient to rise once again.

Q. Does chalk powder reduce friction

Ans: Magnesium carbonate, sometimes known as ‘chalk,’ is a substance that is used to improve the coefficient of friction.

The particles in talcum powder are tiny, but the particles in chalk powder are large. Friction is mostly caused by differences in surface area. Because talcum powder has a smaller surface area than chalk powder, it decreases friction, whereas chalk powder has a higher surface area and increases friction. There is less friction on a smaller surface area, hence it produces less friction.

Q. How does a hovercraft reduce friction

Ans: Slow-moving, low-pressure air vents or currents are ejected downward against the surface of the water below the hovercraft. It is possible to glide effortlessly over the flat surface underneath because of the cushion’s significant reduction in friction.

Q. How does oil reduce friction

Ans: Oil is introduced to the engine in order to minimise friction.

A thin coating of oil is created between the two surfaces when oil is placed between them. The oil coats the moving components’ surfaces, making them slippery as a result of the friction. When they brush against one other, the interlocking between the two surfaces is much decreased because of this layer. It is easier for them to slide over one another, resulting in less friction.

Q. How do you reduce friction in big machinery and cars

Ans: The use of lubricants such as oil and grease, as well as the use of ball bearings between machine elements, can help to reduce friction. A lubricant is a substance that is placed between two surfaces that are in touch with the goal of minimising friction between them.

Q. How to reduce friction between wood

Ans: The friction between the woods can be reduced by polishing the surfaces using the sand papers. Also, special lubricant called as varnish can lower the friction coefficient of several materials. The high static friction coefficient of these elastomers is a common characteristic. Coating with lubricating varnish can effectively reduce the stick-slip effect in actual use.

Q. Reduce friction between two surfaces

Ans: There are many ways to reduce friction between the surfaces in contact.

Polishing the surface helps minimise friction by smoothing out the surface. It is possible to minimise friction by using lubricants such as oil or grease, which may be applied to the surfaces. Ball bearings can be used to lessen the friction between a rolled object and the surface it is rolling on.

Q. What is the effect of reducing friction on a machine

Ans: Increasing the efficiency of a machine while simultaneously minimising the amount of hazardous heat generated between machine elements is the result of reducing friction on the machine. The excessive creation of heat will harm machine parts if friction is not reduced. Furthermore, if the friction isn’t decreased, the process will demand more power.

Also Read:

- Why are there different types of mirrors

- Doppler effect examples

- Is dynamic equilibrium a diffusion

- S polarized vs p polarized

- Example of pyramid

- How to reverse drill direction

- Is freezing point a physical property

- Example of prism

- Neutral equilibrium examples

- Numerical problems on gravitation class 9

= refers to the coefficient of wet friction

= refers to the coefficient of wet friction N

N