Micrometer:

““A micrometer, sometimes known as a micrometer screw gauge, is a device incorporating a calibrated screw extensively used for accurate measurement in mechanical engineering, lab-specific measurements, and other metrological instruments such as dial, vernier, and digital calipers.”

Micrometers are also an essential part of microscopes and telescopes to compute the apparent dia of space matter or infinitesimal substances. The German language device’s usual name is “Messschraube,” which means “the measuring screw.”

English astronomer William Gascoigne first used Micrometer in a telescope with modification in the year 1638.

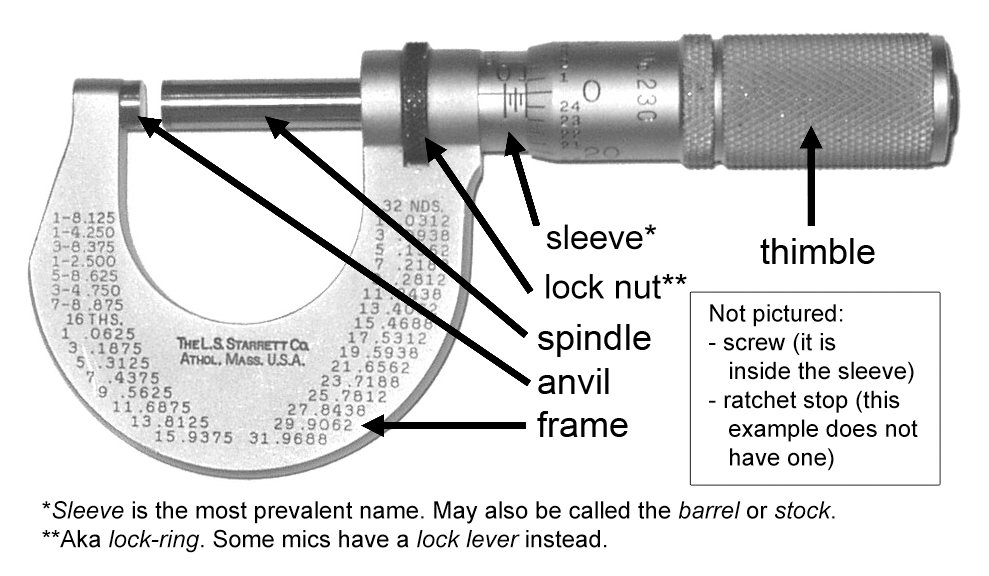

Components of Micrometer:

Three-quarter-ten, Micrometer caliper parts 0001, CC BY-SA 4.0

Micrometer is a scientific measuring tool for accurate linear dimensions i.e. thicknesses, dia, and lengths matter; A Micrometer is a C-shape framed equipped with a movable jaw, usually worked by a vital screw shaped part. A micrometer is composed of multiple subparts as follows:

Anvil

The anvil of a micrometres is the part that remains stationary or mounted on a device frame while the measuring material is on it. The anvil links directly to the frame and differs in form depends on the measurement task. The polished glossy part that the spindle moves toward and that the sample relaxed against.

Sleeve or Barrel:

The sleeve is one of the main parts of the micrometer instruments; the basic measuring technique and accuracy depend on these components. The sleeve is a round-shaped component equipped with the linear scale marking or sometimes with vernier scale markings. In most instruments, the scale is marked in a tight-fitting manner. In standard practice, a rotationally movable cylindrical sleeve has been fitted over the core fixed barrel. The “zeroing” adjustment could be made efficiently by slightly varying the position of the sleeve. This is also known as barrel or stock.

Frame of Micrometer

The frame of Micrometer is a C-shaped frame that holds the anvil and barrel in constant relation to each other in the frame. It is thick and robust made by stainless steel or other rigid material mainly for the reason that it needs to minimalize flexion, expansion, and contraction, which might misrepresent and increase the error in the measurement.

The frame is heavy and has a high thermal mass to stop up significant heating by the hand/fingers that are holding. It’s often covered by insulating plates, that further decrease heat transference. Micrometers operated in a specified temperature at that reads correctly (often 20 °C or 68 °F, which is generally considered as “room temperature”). Otherwise some temperature related might occur. The typical accuracy range for most meter is around 1/100 mm.

Locknut:

The Locknut is a kind of lever mounted in Micrometer that can be used to tighten up or hold the stationary spindle position. It is also some time called lock-ring, or thimble lock, which is very useful momentarily while holding a measurement of a small object.

Screw

The “Screw” of a micrometer is the heart as it controls “Operating principles” the during measurements . Screw mounted inside the barrel. This references the circumstance that the actual name of the instrument was Messschraube in German language, exactly means “measuring screw.”

Spindle

Spindle is a polished cylinder-shaped section that the thimble caused to sliding in the direction of the anvil.

Thimble

The thimble rotates in reference to the barrel on a threaded shaft with 40 threads per inch. Thus, one complete rotation of the thimble, the axial movement is 1/40th, or. 025 inch. As this component is rotated by thumbs so it called Thimble.

Ratchet Stop

A section of device on the end of the handle that restricted applied pressure by gliding at a calibrated force or torque.

Ratchet stop vs. Ratchet thimble on Micrometer

What is the pitch of a micrometer thimble screw?

It’s a screw with a appropriately fix the pitch (the quantity where the thimble drives front or back to get a complete rotation) measures. This has a standard pitch of 0.50 mm (two complete turns are expected to finish the jaws from 1.00 mm).

How to read a Micrometer ?

Measurement using Micrometer:

Micrometer is a scientific measuring tool for accurate linear dimensions i.e. thicknesses, dia, and lengths matter; A C-shape framed equipped with a movable jaw, usually worked by a vital screw shaped part. Micrometers employ a screw and pinion to change trivial axial distances (which is too minimal to quantify accurately) into several rotational scale to read by an accurate magnified scale. This meter’s correctness originates from this basic layout of instrument design. This might be a differential screw,for more advance application. A micrometer’s fundamental principles are as follows:

- The quantity of rotation of a correctly twist screw, mounted perfectly and able to convert a particular amount of rotational motion (and vice versa), through screw’s lead.

- A lead of screw or guide is covering the distance it moves ahead axially with a single full turn (three sixty degree in total). (In many single-start threads, pitch and lead refer to basically the exact identical idea.)

- With a proper lead and main dia. of the screw, a specified quantity of axial shift could be amplified during rotational measure.

- In certain meter, even greater precision is obtained with a metering screw adjuster to maneuver the thimble in much slighter increments than just one thread would permit.

Image Credit : Lookang many thanks to Fu-Kwun Hwang and author of Easy Java Simulation = Francisco Esquembre, Micrometer no zero error, CC BY-SA 3.0

Example of Measurement:

If the lead of a screw is dimension of 1 mm, with the outer dia of 10 mm, the screw’s perimeter will be about 31.4 mm (10π). Hence, an axial movement magnified to a rotational movement. (1 mm axial is equal to 31.4mm rotational movement). This amplification makes it possible for a difference in the dimensions of similar objects that are quantified to equal to a gap in the job of the thimble.

The car odometers scale based micrometer is also available where the information is available in “rollover” format and easy to read. This is also known as “mechanical-digit version micrometer has shown in figure below.

Source of Error for Micrometer

- Zero Error adjustment has to be done. Axial to Rotational conversion for pitch has to be correct.

- Both the gauging tools and the item being measured must be at room temperature for a correct measurement;

- The presence of dust, machine imperfection, and little operator expertise are the main sources of error.

- Generally, the meter needs to be calibrated before utilization.

- During storage, a micrometer should never bare open and it’s anvils or surface has to closed. Sometimes, over-tightening at C-clamp, it may cause enough problem to bend the frame.

Calibration of Micrometer: Testing and Adjusting

Zeroing:

Adjustment of “Zeroing” is required when it read nonzero even its jaws are closed. So small adjustment is required before the use. That is usually called the “Zero Calibration process.”

A little pin spanner is used to turn the sleeve to ensure its zero lines are re-positioned relative to the mark on the thimble in most instruments. There’s generally a hole in the sleeve that is dedicated to the pin of the spanner. This calibration process will cancel a zero error.

Testing:

The accuracy of device is tested by measuring gauge block, standard rod, or similar dimension whose length is to be precise and accurate. A standard 1 inch micrometre’s readout division is 0.001 inch & rated-accuracy approximately ±0.0001 inch.

Adjustment:

Adjustment might restore to precision a meter that found to be away and analysed and has been zeroed. A fix in grinding, lapping, or in replacement parts is necessary for modification during adjustment. In case the error originates in the areas of the meter being worn out of shape and size, then the recovery of precision by this method isn’t possible as it’s work as a basic design fault; For regular practice, it’s frequently far better to purchase a new one instead looking for refurbishment.

Digital Micrometer :

In classic-style analog meter, the thimble is read from the scale manufacturer. Though in market digital variant are equipped with an LCD based screen and advanced in design is more popular digital meter has shown below

Also Read:

- Hammer drill uses

- Why is the sky blue

- Factors affecting solubility

- Why static friction is greater than kinetic

- Solubility

- S polarized

- High friction examples detailed insight and facts

- Reduce friction

- Harmonic oscillator examples

- Hubble sequence and types of galaxies

I am Subrata, Ph.D. in Engineering, more specifically interested in Nuclear and Energy science related domains. I have multi-domain experience starting from Service Engineer for electronics drives and micro-controller to specialized R&D work. I have worked on various projects, including nuclear fission, fusion to solar photovoltaics, heater design, and other projects. I have a keen interest in the science domain, energy, electronics and instrumentation, and industrial automation, primarily because of the wide range of stimulating problems inherited to this field, and every day it’s changing with industrial demand. Our aim here is to exemplify these unconventional, complex science subjects in an easy and understandable to the point manner.

Hi Fellow Reader,

We're a small team at Techiescience, working hard among the big players. If you like what you see, please share our content on social media. Your support makes a big difference. Thank you!