In this article, the topic, “boiler steam pressure” with 17 interesting facts will be summarizing in a brief manner. Boiler is a device which is used to mainly generate the steam.

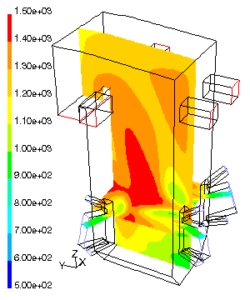

The principle of the boiler is to generate steam by burning the fuel inside the furnace of the boiler. These gases which are in higher temperature are generating to come in concretion with the water vessel where mainly the heat is changes from the water to in the state of steam.

So, the basic working principle of the boiler is to transfer from water to steam with the help of heat energy. When the liquid is boiled at that time inside the boiler temperature is increases and the temperature increases the pressure of the boiler is also increases.

What is boiler steam pressure?

Boiler is a vessel inside of it the liquid substance is heated thus steam can be generate. The liquid not required to boil.

The steam pressure can be explained as; the particular range of the pressure of the heating system at which, the heating system able to convert the water to steam for generating power. A boiler is constructed in this way thus it could able to generate and stand against the pressure of the steam at 300 pound per square inch.

When the steam pressure is increases inside a heating system in this case due to high pressure more amount of heat is applied to produce steam. Increasing with the pressure steam can be generating in a higher temperature. The steam which have higher temperature is carried more amount of energy per pound.

Boiler steam pressure unit:

The unit of the boiler steam pressure is kilopascal or pound per square inch. With the help of flow rate estimate device known as, flow meter, the steam pressure of the boiler can be measure.

The flow meter is an instrument which is mainly used to measure the volumetric flow, linear mass and non linear mass of a gas or liquid substance. The other names of the flow meter in the industrial fields are flow rate sensor, flow gauge, liquid meter and also flow indicator.

Boiler working steam pressure:

The working temperature of the boiler is 20 bars to 80 bars pressure. In this particular range of pressure of the steam for the heating system power can be produce.

If the steam pressure of the boiler is below 20 bars then the power cannot be generate in the desired level as the same way if the steam pressure of the boiler is more than 80 bars then various types of unwanted situation will be arise.

If the steam pressure of the boiler is below than 20 bars then it consider as low steam pressure of the boiler and if the steam pressure of the boiler is more than 80 bars then it consider as high steam pressure of the boiler.

Boiler steam pressure control system:

Boiler steam pressure control system is separate control panel which is driven by electricity. The purpose of the boiler steam pressure control system is to allow input and output from the heating system and to confirm the function of the boiler done in the accurate and safe way.

The boiler steam pressure control system works in two ways. One is as a safety device and second one is as an accuracy device. If the steam pressure is increases then the pressure control system reduce the unwanted pressure from the system and reached to the accurate level to work the system properly.

The operator of the boiler control should be fixed at the range of 5–10 PSI beyond the actual steam pressure to maintain in the heating system. This approves the boiler to stretch low fire, if steam pressure of the boiler is growing; it will stop the boiler to work. The boiler will again start when the steam pressure drops under the differential set on the operator.

Boiler steam pressure reducing valve:

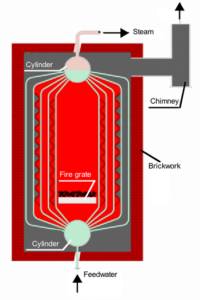

The steam pressure reducing valve is a device which is accurately accommodate the downstream pressure of the steam and automatically monitoring the quantity of valve opening to accommodate the pressure to remain constant nevertheless the flow rate is fluctuate by the springs, diaphragms and pistons.

The location of the steam pressure reducing valve in the boiler where the main water line is comes into house when the main valve is turned off. The lifespan of the pressure reducing valve in a heating system is near about 5 years. After this particular time period the pressure reducing valve should to replace for smooth running of the system.

What is a pressure reducing valve on a boiler?

The pressure reducing valve is a very important part of a heating system. To reduce unwanted pressure from the boiler maintains the desired pressure of the system and helps to prevent any damages and also from accident.

A pressure reducing valve is an instrument which is control the pressure of the gas or liquid substance inside a boiler to achieve a desired value with the help of negative feedback from the regulable pressure. The pressure reducing valve is used for liquids and gases, and an integral instrument with a flow valve, pressure setting, a sensor, a separate pressure sensor, and a restrictor.

Classification of pressure reducing valve on a boiler:-

The pressure reducing valve can be categorized in two sections, they are,

- Pressure reducing regulator valve

- Back pressure regulator valve

2. Spring

3. Actuator

4. Inlet port (high pressure)

5. Outlet port (low pressure)

6. Valve body

7. Valve crown and seat; Image Credit – Wikipedia

Breville dual boiler steam pressure:

A breville dual boiler is constructed in this way thus it could able to generate and stand against the pressure of the steam at 3 bars. When the pressure o the steam in exceed to the limit of 3 bar it consider as the system is facing high steam pressure.

To overcome the high steam pressure to the system a pressure relief valve is use thus excess amount of steam pressure can be reduce without facing any difficulties.

Sage dual boiler steam pressure:

A saga dual boiler is constructed in this way thus it could able to generate and stand against the pressure of the steam at 1.1 bars to 1.3 bars. The steam can be generate at the particular temperature of 100 degree centigrade but working steam pressure temperature for the saga dual boiler is 120 degree centigrade to 123 degree centigrade.

Reducing boiler steam pressure to save energy:

Steam pressure reduction is the lowering of the steam pressure at the boiler plant by means of the pressure setting on the boiler plant master control. Steam pressure reduction affects mainly the high pressure part of the steam system.

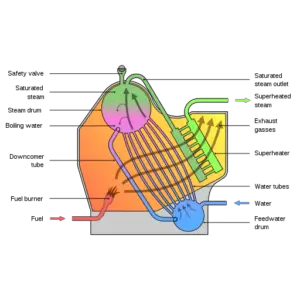

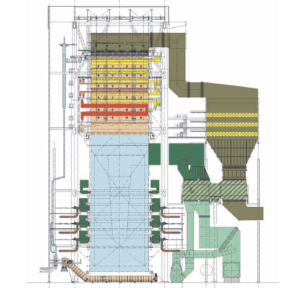

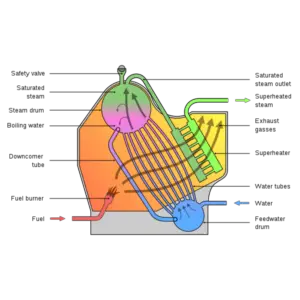

Water tube boiler steam pressure:

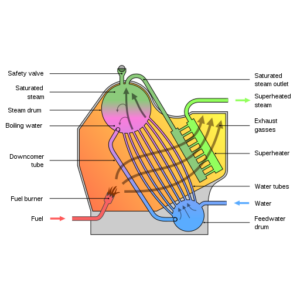

In the power station where a huge amount of power is generated in that place water tube boiler is state. A water tube boiler is constructed in this way thus it could able to generate and stand against the pressure of the steam at 160 bars and superheated steam is generated at the temperature of 550 degree centigrade.

In the water tube boiler water is placed at the inside of the tubes and hot flue gases stays surround of it. The heat of the gases is moved by the walls of the pipes via thermal conduction, heating the water and in final state produce steam.

Espresso boiler steam pressure:

An espresso boiler is constructed in this way thus it could able to generate and stand against the pressure of the steam at the range between 1.0 bar to 1.3 bars. The steam is generated for the espresso boiler at the temperature of 100 degree centigrade and the steam pressure can work properly at the temperature of 110 degree centigrade to 120 degree centigrade.

Recovery boiler steam pressure:

A recovery boiler is constructed in this way thus it could able to generate and stand against the pressure of the steam at 10 MPa at the temperature of 550 degree centigrade. When the steam pressure reach to at the range of 10 MPa then for purpose of the safety the steam pressure is reduced.

Recovery boiler pressure is one type of boiler in where various types of waste heat produce from the method of manufacturing of non ferrous metal, steel, cement, chemical and many more and those equipment of refuse incinerators, industrial furnaces, and transform such recover heat into effective can useful thermal energy.

Residential steam boiler pressure:

Residential steam boiler pressure is constructed in this way thus it could able to generate and stand against the pressure of the steam at very low range. The range of the residential steam boiler pressure will be near about 0.2 pound per square inch to 0.5 pound per square inch.

How does a steam pressure reducing valve work?

The steam pressure reducing valve is a device which is accurately accommodate the downstream pressure of the steam and automatically monitoring the quantity of valve opening to accommodate the pressure to remain constant nevertheless the flow rate is fluctuate by the springs, diaphragms and pistons.

What happens when steam pressure is reduced?

A reduction in steam pressure can also cause an increase in specific volume and, for a given mass flow, an increase in velocity. Fire tube boilers are equipped with a nozzle at the steam outlet which delivers steam to the system.

Low-pressure steam systems don’t exceed 15 pounds per square inch (psi). By extension, they don’t heat water greater than 250 degree Fahrenheit. High-pressure systems, on the other hand, create steam above 15 psi.

Boiler efficiency vs. steam pressure:

The major difference in between the boiler efficiency and steam pressure are listed below,

| Boiler efficiency | Steam pressure |

| The boiler efficiency can be explain as, the ratio in between the heat actually used in generating the steam to the heat liberated to the furnace. | The steam pressure can be explained as; the particular range of the pressure of the heating system at which, the heating system able to convert the water to steam for generating power. |

| Boiler efficiency by the unit of MBTU or in Pounds of steam delivered per hour. | The unit of the boiler steam pressure is kilopascal or pound per square inch. |

Conclusion:

Boiler steam pressure have a inserting role in the boiler. If the boiler steam pressure is increases then also system faces problem even boiler steam pressure is decreases in this case also boiler faces problem. Accurate steam pressure in a boiler system should be stay at normal pressure.