Content: Sequential Logic

Sequential logic definition:

A type of logic in which the previous sequence state of inputs as well as current input can affect the present output state.

What is sequential logic circuit?

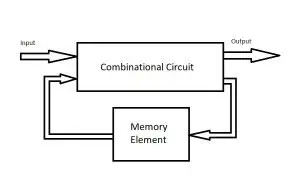

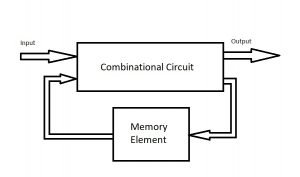

The sequential logic circuit is a combined form of the combinational circuit with a basic memory element. With the presence of a memory element, the circuit can store previous input and output states. At the same time, the sequential logic circuit is generally known as a two-state or bistable device because it has only two stable states, ‘0’ and ‘1’, one state at a time. The memory element in the circuit can store one bit at a time.

This type of circuit has a finite number of inputs with a finite number of outputs. Due to the memory element, this circuit provides the solution to our many problems. A sequential logic circuit is mainly used as a register, counter, analog to digital converter (ADC), etc.

Sequential Logic Diagram | Sequential Logic Architecture :

Types of sequential logic circuits:

Generally, we can differentiate the sequential logic circuit into two basic types:

- A. Asynchronous sequential logic circuit.

- B. Synchronous sequential logic circuit.

Synchronous sequential logic circuits:

The output of this logic circuit depends upon the input pulse and the clock pulse of the circuit. The circuit is synchronized with the clock, i. e. the output can change only after a finite interval of time. Here memory element and the clock is a necessity. Without any clock pulse, there will be no change in output. For a change in one state output to another, this circuit waits for the next change in clock pulse.

This type of circuit may be used to synchronize all the elements present in the circuit, practically for responding to a change in input. There is a need for a finite amount of time for the processed output to occur mainly, known as propagation delay. The propagation delay can vary from element to element. So for a properly working circuit, we need a definite time interval so that all elements can get their time to respond properly. Example of the synchronous logic circuits is flip-flops, synchronous counter, etc.

Asynchronous Sequential logic circuits:

The output of this logic circuit only depends on the input pulse and the sequence of previous input data, This circuit doesn’t have any clock and doesn’t need any synchronization, so the circuit is independent of the clock, which makes it faster than the synchronous sequential logic circuit because the output can change concerning change in input with minimum time required can be affected regardless of time. The only hindrance to the speed of this circuit is the propagation delay of the circuit elements. It consumes less power, low electromagnetic interference.

Asynchronous sequential logic circuits usually perform operations in following cases :

These circuits are mainly used when the speed of operation is a priority, such as in microprocessors, digital signal processing, for internet access, etc. Because of the asynchronous behaviour, the output sometimes may be uncertain, limting the application of the asynchronous sequential logic circuit. Forming this type of circuit is also difficult.

Difference between synchronous and asynchronous sequential logic circuits:

| Synchronous sequential logic circuit | Asynchronous Sequential logic circuit |

| The output of this logic circuit depends upon the input pulse as well as the clock pulse of the circuit. | The output of this logic circuit only depends on the input pulse and the sequence of previous input data. |

| The clock is present in this circuit. | No clock is present in the circuit. |

| The circuit is simple for designing. | The design of this circuit is complex. |

| Relatively slower than that of an asynchronous sequential logic circuit. | Relatively faster working than that of the synchronous sequential logic circuit. |

| State output is always predictable | State output sometimes unpredictable |

| This circuit consumes somewhat high power. | It consumes relatively more minor power. |

Sequential Logic State diagrams:

Sequence logic state diagram is a characteristic diagram of the circuit, in which we can determine the transition between the states concerning the input. In this type of diagram that state is mainly represented as a circle and the change from one state to another is denoted by an arrow, along with that arrow the input pulse is represented, which causing the transition between the state. When there is pulse output the arrow can be represented with the output related to the input pulse. Here the arrow starts with one circle and goes to another circle and sometimes it can come back to the same circle depending upon the condition.

Sequential logic circuit design | Sequential logic design principles

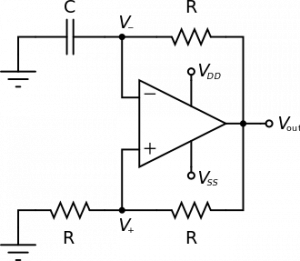

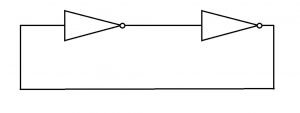

We already know that a sequential logic circuit combines the combinational circuit with a memory element. And for the memory element, we need a static memory element to store data in circuitry. So for creating a static memory cell in the circuit, we use inverters.

Steps of Sequential logic circuit design:

- Create a state diagram for the required sequential circuit with the desired output states.

- Convert the state diagram into a state table.

- Chose the flip-flop as your requirement and which is satisfying all the needed conditions, use the characteristic table or excitation table for selection of the flip flop.

- Minimize the input functions to the flip flop with the help of a K- map or required Boolean algorithms.

- Use the simplified function to design the sequential circuit and if the combinational circuit is needed for the required output add it accordingly.

- Finally, check for the required output through the circuit.

By following the above step we can design any sequential circuit required.

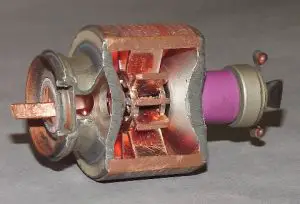

Sequential MOS logic circuits:

As we know that a sequential logic circuit is a combination of the combinational circuit with a memory element. And for the memory element, we need a static memory element so that it can store data, in circuitry. So for creating a static memory cell in circuitry we use inverters.

A static memory cell can be created by two or any even number of inverters connected in series with feedback. It has two stable states, but one stable state at a time, and the stable output state is concerning the input. When a noise (as a voltage or other form) adds up to the output, which can make the circuitry unstable, and the output may not be stable at a definite state, but as the noise crosses through either of the inverters, it gets eliminated as this circuit is regenerating always trying to return to a definite stable state, which helps us to create an active and regenerative memory cell.

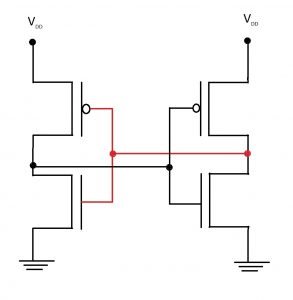

The above diagram is the CMOS circuit is of the memory cell (two inverters connected in the feedback). Where this circuit will be stable at ‘0’ or ‘1’ considering the input supplied (voltage) through the input, this memory cell in CMOS is a static memory cell. And by combining the CMOS circuit of this memory cell with the combinational CMOS circuit, we can design the sequential circuit CMOS circuit.

Combinational logic vs Sequential Logic:

| Combinational Logic | Sequential Logic |

| It is a type of digital logic that is composed of numerous Boolean circuits, and its output only depends on current inputs. | It is also a type of digital logic composed of a combinational as well as a memory element, its output not only dependent on the current input but can also be manipulated by the sequence of previous inputs. |

| Its circuit is relatively costly. | Its circuit is relatively cheap. |

| The clock is not there in its circuitry. | The clock is a necessary element in the synchronous sequential circuit. |

| There is no memory element in its circuitry. | There must be a memory element in the circuitry of this logic. |

| There is no feedback circuitry is present. | For manipulation through past inputs, feedback circuitry is needed. |

| Designing the circuit through logic gates is easy. | Here we can face complications in designing the circuitry due to the requirement of memory elements and feedback. |

| Processing of results is comparatively faster. | After considering every aspect, the output processing can be relatively slower. |

| We can define the input-output relationship through the truth table. | The input-output relationship can be defined through a characteristic table, excitation table, and state diagrams. |

| The requirement of this logic is mainly to perform Boolean operations | Requirement of this logic for storing data, creating counter, registers, etc. |

Sequential logic circuits Applications:

With the finite number of inputs and outputs, the sequential logic circuit is used to construct a finite state machine. It can act as a register, counter, etc. With the help of a combinational circuit, many basic devices can be created like RAM (Random Access Memory), as sequential logic circuit provides us with the facility to store data it opens the door to the microprocessor and Arithmetic logic Circuit.

Sequential Logic Devices:

The output of a sequential logic device can be manipulated by the current input and by the previous input or clock pulses. Sequential devices store the last data with a memory element. With this capability of storing data these devices, open new ways to solve a problem.

Sequential devices are like counter, register, etc.

Sequential Logic chips

Advantages and disadvantages of sequential logic:

Advantages of sequential logic:

A significant advantage of sequential logic is that its circuit contains a memory element that enables storing data and creating a register, counter, and microprocessors. With the use of clock pulse, it can synchronize all the circuitry elements regardless of different propagation delays and provide proper output. Output can be manipulated through current input, past sequence of inputs, and through clock pulse also.

Disadvantages of sequential logic:

Presence of a clock and feedback in the circuitry, the processing of the output can be slower. Complications of the circuit may increase, which can cause difficulty in building the circuitry. The output is sometimes can be uncertain.

Sequential logic history :

Sequential logic is utilized for the development of finite state machine, which is a basic building block of all digital circuitry. For more information click here.

Sequential logic circuits questions and answers | solved problems on sequential logic circuits | FAQ

Q. How does computer ram use sequential logic ?

Q. Is ROM/RAM a combinational or sequential circuit?

Answer: – ROM (Read Only Memory) consists of Encoder, Decoder, Multiplexer, Adder Circuitry, Subtractor Circuitry, etc. The encoder is a combinational circuit that mainly converts one form of data to another format, such as decimal data to binary data. The decoder here is also a combinational circuit. The same goes for Multiplexer, Adder, and Subtractor. All are here is a combinational circuit.

In ROM, we cannot alter the content of the memory. Therefore the output of the ROM is only dependent on the input. So there is no requirement of the past value of input or output. So, ROM has only a combinational circuit in its circuitry.

Whereas for RAM (Random Access Memory), PROM (Programmable read-only memory), EPROM (Erasable Programmable read-only memory), EEPROM (Electrically Erasable programmable read-only memory) has a memory that can alter. In the case of PROM, it can be programmed once after manufactured. RAM, EPROM, EEPROM, where can change the state. In this type of memory, we always need the sequential circuit for proper operation, as here, there is a need for past input and output values. The current output can be altered with the previous sequence of data. Therefore this type of memory needs a sequential circuit.

Q. Is ripple carry adder an example of sequential circuit Why?

Answer: – A ripple carry adder is a digital circuitry which performs addition arithmetic of two different binary number. It can be designed with the cascading of a full adder connecter to the carry output, where the carry output of a full adder is connected to the input of the next full adder. As we see here, one full adder is connected to the next adder as feedback, here the output of one full adder can manipulate the output of another full adder. So here we see that past output can manipulate the present output of the circuit. Therefore ripple carry adder can be considered a sequential circuit.

Q. Why are non blocking assignments used in sequential circuits in Verilog ?

Answer: – In non-blocking assignments when the first-time step takes place, the evaluation of the right-hand side expression of the non-blocking statement takes place after that revision of the left-hand side of the non-blocking statement takes place, and at the end of the time step, the evaluation of left-hand statement takes place.

As non-blocking assignments do not block the evaluation of any sequential statements, the execution of these assignments simultaneously or parallelly occurs. So, for creating a sequential logic circuit in Verilog we always have to consider clocked block and non-blocking assignments. With the help of non-blocking assignments, we can eliminate the race around condition in the sequential circuitry.

Q. Define asynchronous sequential logic circuits ?

Answer : explained in asynchronous sequential logic circuits section.

Q. How many flip flops are required to build a sequential circuit which has 20 states.

Answer: – Flip Flops is a basic memory element in the sequential digital circuit, which has two stable states, and those two states can be represented as ’0’ and ‘1’, but It can store a single bit at a time.

According to binary encoding, n number of flip flops can represent maximum 2n

Here we need 20 states of a sequential circuit

So 2n = 20

After solving the above equation, we get n = 4.322

As for, 24 there are only 16 states, but we need 20 states. Here we are 4 more states for working so we have to choose a number higher than 4. So, we will be using n=5 where 25 has 32 states, which is sufficient enough for 20 states.

Whereas in one-hot encoding there the number of flip flops required for n states is n. so there we need 20 flip flops for 20 states.

Q. How can a sequential chip be made from combinational chips alone

Answer: – When a combinational logic circuit is connected with a feedback path, the resulting circuit is a sequential logic circuit.

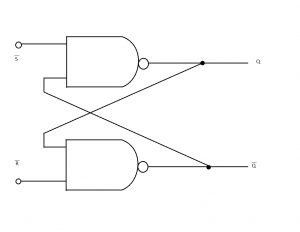

If we go to the diagram of essential memory elements like a flip flop, latches, we can see that the flip-flop can be created with the help of AND gate, NAND gate, NOR gate, etc., when they are connected with feedback to each other.

The diagram shows two NAND gates connected with a feedback path that forms the S-R flip flop circuit. In this way, a combinational circuit can be converted into a sequential circuit.

Q. Working principle of astable sequential logic circuits

Answer:- An astable sequential logic circuit does not have any stable state as output i.e it is not stable in any state. The output continuously transits from one state to another. This type of circuit can be used as an oscillator, such oscillator for generating clock pulse in a circuit. An example of an astable circuit is a ring oscillator.

For more articles click here