In this article, the topic, “is a boiler electric or gas” with 13 facts on different boilers will be discuss in a brief manner. The entire modern boilers are operating with the electricity.

A boiler can be electric or gas both. The electric boilers are transforming the electricity into heating in spite of burning the fossil fuels. A boiler which is driven by boiler is appropriate for the properties which are not connected with the gas network or small size apartment or flat with a lower demand hot and heating water.

Is a boiler electric or gas?

After remove the access panel of the heater from the side of the boiler and look for the pilot light. If we can observe a pilot light is present in the heater, then we can say that it is a type of gas boiler. Electric heaters do not come up with such lights.

How to know the type of boiler?

In general there are three classification of any boiler. The first classification is combi boiler, second classification is heat boiler and last one is system boiler.

How we can understand which type of the boiler is belong is describe below,

Combi boiler:-

A combination or combi boiler is a type of gas boiler which is combination with the central heating system water heating system into a single part body to make hot water as requirement. A separate tank for the heating the water is not required for the combi boiler. The efficiency of the combi boiler is more effective.

Combi boiler work as a one gas boiler system for this reason the space requirement for this is very minimum in a short place easily combi boiler easily can be installed.

Recognize of a combi boiler:-

When we observe a boiler easily can be recognize the combi boiler by its size. The size of the combi boiler is small size or medium size and installed in the apartments for full filling the demands of the hot water.

Five copper tubes are comes from the bottom section of the boiler and there will be no presence of the external pump or cold water tank and hot water tank for the unit of heating system is together with a single body unit.

Heat boiler:-

Another term for the heat boiler is regular boiler. The heat boiler not providing the hot water demand in the way combi boiler does. The hot water is store into the hot water storage tank until the hot water is needed to be distributing to a shower or tap.

Heat boiler system contains both the hot storage and cold storage for this reason a large amount of space is required.

Recognize of a heat boiler:-

When we observe a boiler easily can be recognize the heat boiler by its size. The size of the heat boiler is larger and installed in the apartments for full filling the demands of the hot water.

The external pump system is needed for the heat boiler and also both cold water tank and hot water tank for the unit of heating system is present. Two copper tubes are comes from the bottom section of the boiler.

System boiler:-

System boilers heat the central heating system and also generate hot water for the water storage system. The system boiler directly takes water from the mains as converse to using an expansion and feed tank just like a regular boiler.

In generally where high amount of hot water is required in that case system boiler is needed. The system boiler at a same time in two bathrooms hot water can provide without using any cold water tank.

Recognize of a system boiler:-

When we observe a boiler easily can be recognizing the system.

Three copper tubes are comes from the bottom section of the boiler and there will be no presence of the external pump. In the system boiler hot water tank for the unit of heating system can be observe.

How to identify gas boiler?

When we observe a boiler easily can be recognize the gas boiler by its size. The size of the gas boiler is larger and installed in the apartments for full filling the demands of the hot water. The external pump system is needed for the gas boiler and also both cold water tank and hot water tank for the unit of heating system is present. Two copper tubes are comes from the bottom section of the boiler.

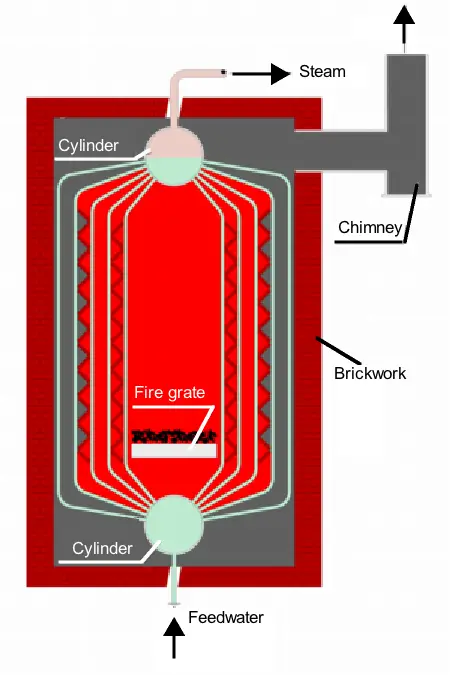

Advantages of gas boiler:-

The advantages of the gas boiler are listed below,

- The cost of the gas boiler is cheaper than the electric boiler.

- Gas boiler can full fill the high scale demand for hot water and heating.

- Installation cost for the gas boiler is low.

- More verities of the gas boiler mean more available options in the market.

Disadvantages of the gas boiler:-

The disadvantages of the gas boiler are listed below,

- For installation a large amount of space is required.

- Lots of moving parts are present in the gas boiler for this reason lots of problem can be arise.

- Leakage of the carbon monoxide can be more.

- Maintenance is required in a year.

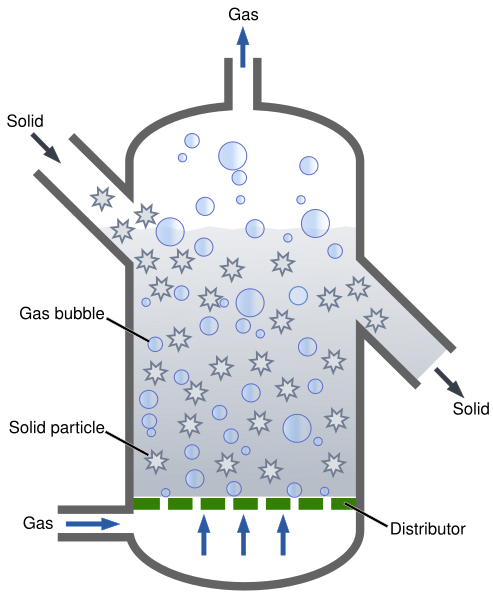

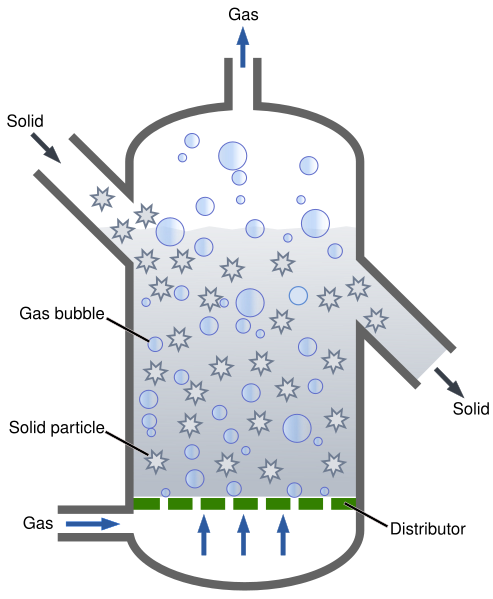

Image Credit – Wikimedia Commons

Does a boiler use gas or electricity?

Without electricity the boiler could not runs its function. For running may be little amount of electricity is needed but without electricity the boiler could not run. For display screen, thermometer and also back lighting bulbs electricity required. The electricity also helps to keep the apartment heated and supplied hot water. For ignition of the boiler electricity play a important role.

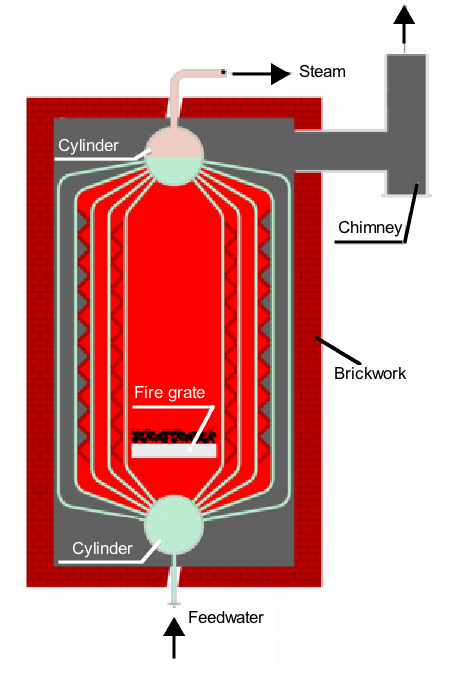

Advantages of electric boiler:-

The advantages of the electric boiler are listed below,

- The parts of the electric boiler are very less moves for this reason problems are very less arise.

- Installation of an electric boiler is easy there is not required any flue pipe.

- Carbon monoxide leakage can be appear in the electric boiler is zero percentage.

- Operation of the electric boiler is not noisy.

- Emission is not appearing while heat the apartment.

Disadvantages of electric boiler:-

The disadvantages of the electric boiler are listed below,

- Installation cost of the electric boiler is expensive.

- Electricity is expensive comparative to the natural gas.

- While defection is appearing in the electric boiler the maintenance cost will be became expensive.

- Heating demand cannot match for the large size property.

- Most of electricity is create for the burning of fossil fuels.

Image Credit – Wikimedia Commons

How to identify electric boiler?

In general there are three classification of any electric boiler. The first classification is combi boiler, second classification is heat boiler and last one is system boiler.

How we can understand the identification of a boiler is listed below,

- Recognize of a combi boiler

- Recognize of a heat boiler

- Recognize of a system boiler

Recognize of a combi boiler:-

When we observe a boiler easily can be recognize the combi boiler by its size. The size of the combi boiler is small size or medium size and installed in the apartments for full filling the demands of the hot water.

Five copper tubes are comes from the bottom section of the boiler and there will be no presence of the external pump or cold water tank and hot water tank for the unit of heating system is together with a single body unit.

Recognize of a heat boiler:-

When we observe a boiler easily can be recognize the heat boiler by its size. The size of the heat boiler is larger and installed in the apartments for full filling the demands of the hot water.

The external pump system is needed for the heat boiler and also both cold water tank and hot water tank for the unit of heating system is present. Two copper tubes are comes from the bottom section of the boiler.

Recognize of a system boiler:-

When we observe a boiler easily can be recognizing the system.

Three copper tubes are comes from the bottom section of the boiler and there will be no presence of the external pump. In the system boiler hot water tank for the unit of heating system can be observe.

Is a combi boiler gas or electric?

A combi boiler can be both gas boiler and electric boiler. The electric boilers work same as the gas boiler but to generate the central heating system and to warm the water electricity is needed. Only by the electric combination boiler we can warm the water and full fill our desire.

Do all combi boilers use gas?

The simple answer is no. All combi boilers do not use gas to operate the function. A combi boiler can be both gas boiler and electric boiler. The electric boilers work same as the gas boiler but for the generating the central heating system and to warm the water electricity is needed.

Can you have a combi boiler without gas?

Electric combi boilers do not run off gas or oil so the electric boiler is not depend upon the existing heating system to generate heat in the apartments. The installation cost became very less and making fit also easier. The parts for the electric combi boiler is less for this reason maintenance cost also became cheaper.

Is a back boiler gas?

Yes, a back boiler is gas. The size of the back boiler is very less. Compact boiler is attached at the back portion of an open fireplace hearth.

The back boiler is situated behind a gas fire and helps to generate hot water and central heating system.

Is a worcester boiler gas or electric?

Worcester boiler is a type of gas boiler. High energy efficiency, comfort and reliability can be easily got through the Worcester boiler. Mainly the gas, propane and oil fuel differs so as suitability we can choose the boiler for any apartment.

What type of boiler is a Worcester?

Worcester boiler is a type of gas boiler. Greenstar is named for the all Worcester boiler. Gas, propane and oil fuel is used in this type of gas fired boiler.

Is a vaillant boiler gas or electric?

Vaillant boiler is a type of gas boiler. The working efficiency for this type of boiler is near about 98 percentages. Installing an energy efficient vaillant boiler in your home can make a huge difference in keeping your energy costs down.

What type of boiler is a Vaillant Boiler?

Vaillant boiler is a type of combination gas boiler. The working efficiency for this type of boiler is near or more than about 98 percentages.

Is a baxi boiler gas or electric?

A baxi boiler is a gas boiler and 180 litres storage provides faster, energy efficient and reliable heat and hot water.

Is a system boiler gas or electric?

An electric boiler relies on electricity to generate heat, and they can be highly effective at warming a home or a home’s water supply. An electric boiler tends to be less expensive than gas boilers, but you must do your research on local costs to before hiring a contractor.

What type of boiler is system boiler?

System boiler is electric boiler. To boil the water required to keep us warm and comfortable, system boilers use the mains as a heat source or sometimes bottled gas or oil.Three copper tubes are comes from the bottom section of the boiler and there will be no presence of the external pump. In the system boiler hot water tank for the unit of heating system can be observe.

Conclusion:-

A boiler can be both electric and gas.