To change the direction of piping, pipe elbows are used. It is important to find pipe elbow dimensions for making a turn of desired radius.

This article discusses about different types of elbows and formulae to calculate their dimensions.

What is elbow in piping?

The path of piping is not always straight, it makes a turn at the end as required.

Elbows are the connectors between two pipes that are inclined at some angle. Elbow contains two openings at a specific angle where the pipes are fixed. Elbows usually come in 90 degrees, 45 degrees or 22.5 degrees.

What is the use of elbow in pipe fitting?

When there is a need to change the direction of fluid flow, the piping system needs to be bent.

This bent cannot be achieved directly by bending the PVC pipe as it is brittle in nature. An elbow is used which connects two straight pipes in angle. This way the direction of piping system is changed and hence the direction of fluid flow.

How do you calculate pipe length elbow?

To calculate the length of the pipe elbow, we need the distance between the ends of two pipes that need to be connected and the angle subtended by elbow.

Lets take an example of 90 degree pipe elbow for which pipe end distance (radius of elbow) is 300 mm.

Circumference of circle is given by-

Circumference = 2πr

90 degree elbow covers 0.25x circumference of circle. Hence, the length of pipe elbow- 0.25 x circumference of circle with radius 300mm.

What is the formula of 90 degree elbow?

Take off is defined as the length of material removed to make the pipe and fitting of a specified length.

The formula for 90 degree elbow is given below-

A = tan(45) x 1.5D X 24.5

Where,

D is diameter of elbow in inch

A is elbow center take off

What is the length of a 90 degrees elbow?

90 degrees elbow makes one quarter of a full circle. To find the length of 90 degrees elbow, we find the circumference of circle and then multiply it by 0.25.

The circumference of circle is given by the formula:

Circumference = 2πr

Hence the length of elbow becomes- 0.25 x circumference

What is the radius of pipe elbow?

On the basis of length of radius, elbows are classified into types- long radius elbow and short radius elbow.

Radius of curvature is around 1.5 times the nominal diameter of the pipe for long radius elbows. On the other hand, radius of curvature is equal to the nominal diameter of the pipe for short radius elbows.

Short radius elbows are used where space limitation is there and abrupt change is required.

How do you measure 45 degrees elbow length?

A 45 degrees elbow makes 1/8 th of a full circle. Hence, the length of 45 degrees elbow will be equal to 0.125 times the circumference of circle.

If the radius of curvature is r, then circumference of circle is given by-

Circumference = 2πr

Where, the length of 45 degrees elbow will be–

L = 0.125 x 2 x π x r

What is the formula of 45 degree elbow?

We have discussed above the formula for calculating take off for 90 degrees elbow.

For calculating take off length for 45 degrees elbow, we use the formula given below-

A = tan(22.5) x 1.5 D x 24.5

Where,

D is diameter of elbow in inch

A is elbow center take off

How many types of pipe elbows are there?

The pipe elbow can be classified on the basis of angle and the length of radius.

On the basis of angle subtended, the pipe elbows are classified as-

- 90 degrees elbow

- 45 degrees elbow

- 180 degrees elbow

For special purposes, 60 degrees and 120 degrees elbows are also made.

On the basis of length of radius, elbows are classified as-

- Long radius elbow- The radius of curvature is 1.5 times the nominal diameter of the pipe.

- Short radius elbow- The radius of curvature is equal to the nominal diameter of the pipe, short radius elbows are used in places where space is very less.

How do I straight pipe my elbow?

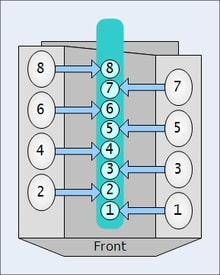

Miter bend is a type of bend in which the pipes are first cut at various angles and then joint together from ends to make an elbow in the piping.

A typical 90 degrees miter bend is made by joining ends of two pipes each cut at 45 degrees. These pipes are usually welded to each other.

Image credits: Wikipedia

What is the take off for a 6 inch 90 degrees elbow?

The formula for 90 degrees elbow is-

A = tan(45) x 1.5 D x 24.5

Where,

D is diameter of elbow in inch

A is elbow center take off

Substituting D as 6, we get elbow center take off, A as 220.5

How do you join different size PVC pipes?

We can use reducers and bushings for connecting PVC pipes of different sizes.

- For connecting a larger diameter pipe with smaller diameter pipe, we use a reducer to make a coupling.

- For connecting a larger fitting to a smaller pipe, we use a reducing bushing.

The reducers and bushings come in various diameters.