Iron (Fe) is a chemical element that belongs to the transition metals group in the periodic table. It is widely known for its importance in various industries, including construction, manufacturing, and medicine. The electron configuration of iron, specifically Fe2+ and Fe3+ ions, plays a crucial role in understanding its chemical properties and reactivity. In this article, we will delve into the electron configuration of Fe, Fe2+, and Fe3+, exploring their significance and implications in different contexts. So, let’s dive in and unravel the mysteries of iron’s electron configuration.

Key Takeaways

- The electron configuration of Fe, Fe2+, and Fe3+ can be determined by following the Aufbau principle, Hund’s rule, and the Pauli exclusion principle.

- Fe has the electron configuration [Ar] 3d^6 4s^2, Fe2+ has the electron configuration [Ar] 3d^6, and Fe3+ has the electron configuration [Ar] 3d^5.

- The electron configuration of Fe2+ and Fe3+ ions is obtained by removing electrons from the 4s orbital first before removing from the 3d orbital.

- The electron configuration of Fe, Fe2+, and Fe3+ influences their chemical properties and reactivity.

on in the periodic table. By studying electron configuration, we can unravel the fascinating world of atoms and their interactions.

Iron (Fe) Electron Configuration

Iron (Fe) is a fascinating element that plays a crucial role in our everyday lives. From construction materials to the transportation industry, iron is widely used due to its strength and versatility. Understanding the electron configuration of iron is essential in comprehending its chemical properties and behavior. In this section, we will explore the standard electron configuration, subshell electron configuration, and condensed and abbreviated electron configuration of iron.

A. The Standard Electron Configuration of Iron (Fe)

The standard electron configuration of an atom describes the distribution of electrons in its various energy levels and orbitals. For iron (Fe), which has an atomic number of 26, the standard electron configuration is as follows:

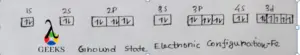

1s2 2s2 2p6 3s2 3p6 4s2 3d6

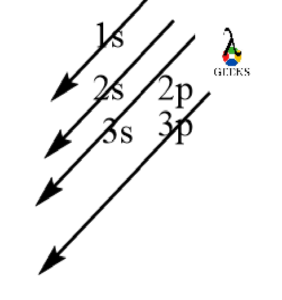

Let’s break this down. The first number represents the principal energy level (n), followed by the letter indicating the type of subshell (s, p, d, or f), and finally, the superscript denotes the number of electrons in that subshell. In the case of iron, the electron configuration starts with the 1s subshell and gradually fills up the subsequent subshells until it reaches the 3d subshell.

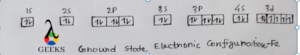

Ground state electronic configuration of Fe

B. Subshell Electron Configuration of Iron (Fe)

To delve deeper into the electron configuration of iron, let’s focus on the subshells. The subshells in iron’s electron configuration are:

- 1s

- 2s

- 2p

- 3s

- 3p

- 3d

Each subshell can hold a specific number of electrons. The s subshell can hold a maximum of 2 electrons, the p subshell can hold a maximum of 6 electrons, and the d subshell can hold a maximum of 10 electrons. In the case of iron, the 3d subshell can hold up to 10 electrons, but in its ground state, it only has 6 electrons.

C. Condensed and Abbreviated Electron Configuration of Iron (Fe)

While the standard electron configuration provides a detailed account of the electron distribution in iron, it can be quite lengthy. To simplify the representation, we can use condensed and abbreviated electron configurations.

The condensed electron configuration of iron is written as:

[Ar] 4s2 3d6

The [Ar] represents the electron configuration of the noble gas argon (Ar), which has the same electron configuration as the filled inner shells of iron. By using the noble gas notation, we can condense the electron configuration and focus on the outermost energy levels.

Additionally, we can further abbreviate the electron configuration by only indicating the valence electrons. The valence electrons are the electrons in the outermost energy level, which are responsible for the chemical properties and reactivity of an element. In the case of iron, the abbreviated electron configuration is:

4s2 3d6

This notation emphasizes the valence electrons and their involvement in chemical reactions.

Understanding the electron configuration of iron is crucial in comprehending its chemical behavior and its ability to form different oxidation states. By knowing the electron arrangement, scientists can predict the element’s reactivity and its interactions with other elements.

In conclusion, the electron configuration of iron provides valuable insights into its atomic structure and chemical properties. The standard electron configuration, subshell electron configuration, and condensed and abbreviated electron configuration all contribute to our understanding of iron’s behavior. By delving into the world of iron’s electron configuration, we gain a deeper appreciation for this essential element and its role in our daily lives.

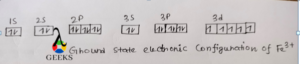

Fe3+ Ground State Electron Configuration

When 3 electrons are removed from neutral fe atom fe3+ ion is formed. The ground state fe3+ electron configuration is 1s2 2s2 2p6 3s2 3p6 3d5. First 2 electrons are removed from 4s orbital as because it has higher energy than 3d orbital and then 1 electron removed from 3d orbital making the valance shell electronic configuration of fe3+ is 3d5.

When 3 electrons are removed from fe atom it contains 5 electrons in the outermost shell i.e. 3d orbital has 5 electrons which is half-filled. As fe3+ ion has stable half-filled 3d orbital and also 1s,2s, 3s orbitals have fulfilled 2 electrons and 3p orbital have stable fulfilled 6 electrons in them it is more stable than fe atom where fe atom has 6 electrons in 3d orbital.

Fe3+ Abbreviated Electron Configuration

To know the abbreviated fe3+ electron configuration first of all we must know the abbreviated electronic configuration of fe atom. The abbreviated fe electron configuration is [Ar] 3d6 4s2. By counting the electrons from 1s to 3p orbital we find that there is a total number of 18 electrons and we replace it by writing in the form of [Ar].

When 3 electrons are realized from fe atom, fe3+ ion is formed and the electronic configuration of fe3+ ion in abbreviated form is [Ar] 3d5 i.e. 2 electrons are removed from 4s orbital as it is higher in energy than 3d orbital and then 1 electron is removed from remaining 3d orbital making it stable half-filled electronic configuration of fe3+ ion.

Fe3+ Condensed Electron Configuration

To know the condensed fe3+ electron configuration first of all we must know the condensed electronic configuration of fe atom. The condensed electronic configuration of fe is [Ar] 3d6 4s2. By counting the electrons from 1s to 3p orbital we find that there is a total number of 18 electrons.

When 3 electrons are realized from fe atom, fe3+ ion is formed and the electronic configuration of fe3+ ion in condensed form is [Ar] 3d5 i.e. 2 electrons are removed from 4s orbital and 1 electron is removed from remaining 3d orbital making it stable half-filled electronic configuration of fe3+ ion.

Fe3+ Noble gas Electron Configuration

When 3 electrons are removed from neutral fe atom fe3+ ion is formed. The noble gas fe3+ electron configuration is 1s2 2s2 2p6 3s2 3p6 3d5. 1st 2 electrons are removed from 4s orbital as because it has higher energy than 3d orbital and then 1 electron removed from 3d orbital making the valance shell electronic configuration of fe3+ is 3d5.

When 3 electrons are removed from fe atom it contains 5 electrons in the outermost shell i.e. 3d orbital has 5 electrons which is half-filled. By counting the electrons from 1s to 3p there are a total of 18 electrons i.e. fe3+ acquire nearest noble gas configuration of [18Ar] 3d5.

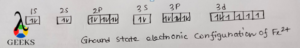

Fe2+ Ground State Electron Configuration

When 2 electrons are removed from neutral fe atom fe2+ ion is formed. The ground state fe2+ electron configuration of fe2+ is 1s2 2s2 2p6 3s2 3p6 3d6. 2 electrons are removed from 4s orbital as it has higher energy than 3d orbital making the valance shell electronic configuration of fe2+ is 3d6.

When 2 electrons are removed from fe atom it contains 6 electrons in the outermost shell i.e. 3d orbital has 6 electrons. fe2+ is less stable than fe3+ as fe2+ has 6 electrons in d shell which is just 1 electron excess to the stable half-filled d5 configuration of fe2+ ion. Also it is less stable than fe atom due to the fact every charged species is less stable than neutral atom.

Fe2+ Subshell Electron Configuration

we know elemental Fe is neutral in nature it also contain same no of electrons in it i.e. it has 26 electrons as well. We distribute the 26 electrons in various subshell which is done according to aufbau principle. The subshell fe electron configuration is 1s2 2s2 2p6 3s2 3p6 4s2 3d6

When 2 electrons are removed from 4s subshell fe2+ ion is formed. The subshell electronic configuration of fe2+ is 1s2 2s2 2p6 3s2 3p6 3d6. From the subshell electronic configuration of fe2+ ion we see that there are 2 electrons in 1s subshell,2 each in 2s and 3s subshell, 6 electrons in both 2p and 3p subshell and 6 electrons in the last 3d subshell.

Fe2+ Condensed Electron Configuration

To know the condensed electronic configuration of fe2+ first of all we must know the condensed electronic configuration of fe atom. The condensed electronic configuration of fe is [Ar] 3d6 4s2. By counting the electrons from 1s to 3p orbital we find that there is a total number of 18 electrons.

We also know that 18 electrons are present in noble gas Ar and we replace it in the electronic configuration of fe by writing it in the form of [Ar]. When 2 electrons are realized from fe atom, fe2+ ion is formed and the electronic configuration of fe2+ ion in condensed form is [Ar] 3d6 i.e. 2 electrons are removed from 4s orbital.

Fe2+ Noble gas Electron Configuration

When 2 electrons are removed from neutral fe atom fe2+ ion is formed. The noble gas fe2+ electron configuration of fe2+ is 1s2 2s2 2p6 3s2 3p6 3d6. These 2 electrons are removed from 4s orbital as because it has higher energy than 3d orbital.

When 2 electrons are removed from fe atom it contains 6 electrons in the outermost shell i.e. 3d orbital has 6 electrons. By counting the electrons from 1s to 3p there are a total of 18 electrons i.e. fe2+ acquires nearest noble gas configuration of [18Ar] 3d6.

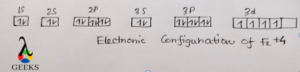

Predicting the Electron Configuration for Fe+4 Ion

When it comes to understanding the electron configuration of ions, it’s important to know that ions are formed when atoms gain or lose electrons. In the case of the Fe+4 ion, we are dealing with an iron ion that has a charge of +4. To predict the electron configuration of Fe+4, we need to consider the electron configuration of the neutral iron atom (Fe) and the number of electrons it has gained or lost.

The electron configuration of a neutral iron atom (Fe) is 1s^2 2s^2 2p^6 3s^2 3p^6 4s^2 3d^6. This configuration tells us that iron has 26 electrons distributed across its electron shells and subshells. However, since the Fe+4 ion has a charge of +4, it means that it has lost 4 electrons.

To determine the electron configuration of Fe+4, we start by removing the 4 electrons from the neutral iron atom‘s highest energy level, which is the 4s subshell. This leaves us with the electron configuration of Fe+4 as 1s^2 2s^2 2p^6 3s^2 3p^6 3d^6.

The Role of Electron Configuration in Stability of Ions

The electron configuration of an ion plays a crucial role in determining its stability. In the case of Fe+4, the electron configuration 1s^2 2s^2 2p^6 3s^2 3p^6 3d^6 is significant because it fulfills the stability requirements for the Fe+4 ion.

To understand why this electron configuration is stable, we need to consider the concept of the noble gas configuration. Noble gases, such as argon (Ar), have completely filled electron shells and are known for their stability. By looking at the electron configuration of Fe+4, we can see that it is abbreviated as [Ar] 3d^6. This notation indicates that Fe+4 has the same electron configuration as argon, except for the 3d subshell.

By achieving a configuration similar to a noble gas, Fe+4 attains a more stable electron arrangement. This stability is due to the fact that the 3d subshell is half-filled, which is a relatively stable configuration. The half-filled 3d subshell provides a balance between the repulsion and attraction of electrons, resulting in increased stability for the Fe+4 ion.

In summary, the electron configuration of Fe+4, 1s^2 2s^2 2p^6 3s^2 3p^6 3d^6, is predicted by removing 4 electrons from the neutral iron atom‘s 4s subshell. This configuration fulfills the stability requirements for the Fe+4 ion by achieving a configuration similar to a noble gas, with a half-filled 3d subshell. Understanding the electron configuration of ions is crucial in comprehending their stability and chemical properties.

How many electrons are in Fe3+?

The ground state fe3+ electron configuration is 1s2 2s2 2p6 3s2 3p6 3d5. We see from electronic configuration that there are a total of 23 electrons out of which 6 electrons in s-orbital, 12 electrons in p-orbital, and 5 electrons in d orbital.

Does Fe3+ have a noble gas electronic configuration?

No, fe3+ does not have a noble gas electronic configuration. fe3+ contains a total of 23 electrons which does not match with any noble gases.

Application of Electron Configuration in Predicting Chemical Behavior

The electron configuration of an atom plays a crucial role in determining its chemical behavior. By understanding the arrangement of electrons within an atom, scientists can predict how it will interact with other atoms and molecules. Let’s explore some of the applications of electron configuration in predicting chemical behavior.

-

Chemical Reactivity: The electron configuration of an atom influences its reactivity. Atoms with incomplete outer electron shells tend to be more reactive as they seek to achieve a stable electron configuration. For example, iron (Fe) has an electron configuration of 1s2 2s2 2p6 3s2 3p6 4s2 3d6. The presence of two unpaired electrons in the 4s and 3d orbitals makes iron prone to forming compounds and participating in chemical reactions.

-

Formation of Ions: Electron configuration also helps in understanding the formation of ions. When an atom gains or loses electrons, it forms an ion. For instance, iron can form two common ions: Fe2+ and Fe3+. Fe2+ is formed by removing two electrons from the 4s orbital, resulting in an electron configuration of 1s2 2s2 2p6 3s2 3p6 3d6. On the other hand, Fe3+ is formed by removing three electrons, leading to an electron configuration of 1s2 2s2 2p6 3s2 3p6 3d5. The electron configuration of these ions affects their chemical properties and reactivity.

-

Stability of Compounds: The electron configuration of an atom also influences the stability of compounds it forms. Atoms tend to form compounds that allow them to achieve a stable electron configuration, often resembling that of a noble gas. For example, iron can form compounds with oxygen to create iron oxides, such as Fe2O3. In this compound, iron loses three electrons to achieve a stable electron configuration similar to argon (Ar).

Role of Electron Configuration in Understanding Periodic Trends

The periodic table is organized based on the electron configuration of elements, and understanding electron configuration helps in deciphering various periodic trends. Let’s explore the role of electron configuration in understanding these trends.

-

Atomic Size: The electron configuration influences the size of an atom. As you move across a period from left to right, the atomic size generally decreases. This is because the number of protons in the nucleus increases, resulting in a stronger attraction for the electrons in the same energy level. However, when moving down a group, the atomic size increases due to the addition of new energy levels. For example, iron (Fe) is larger than oxygen (O) because it has additional energy levels.

-

Ionization Energy: Ionization energy is the energy required to remove an electron from an atom. The electron configuration affects the ionization energy of an element. Elements with a stable electron configuration, such as noble gases, have high ionization energies because it is difficult to remove an electron from a stable configuration. In contrast, elements with incomplete outer electron shells have lower ionization energies as they are more willing to lose or gain electrons to achieve stability.

-

Electronegativity: Electronegativity is a measure of an atom’s ability to attract electrons in a chemical bond. The electron configuration influences an atom’s electronegativity. Elements with a high electronegativity tend to have nearly filled or completely filled outer electron shells, such as the halogens. Iron, with its electron configuration of 1s2 2s2 2p6 3s2 3p6 4s2 3d6, has a moderate electronegativity compared to elements like oxygen or fluorine.

In conclusion, electron configuration plays a crucial role in predicting the chemical behavior of atoms and understanding periodic trends. By analyzing the arrangement of electrons within an atom, scientists can make informed predictions about an element’s reactivity, ion formation, stability of compounds, and its position in the periodic table. This knowledge is essential in various fields, including chemistry, materials science, and engineering.

Conclusion

In conclusion, the electron configuration of iron (Fe) and its ions Fe2+ and Fe3+ play a crucial role in understanding their chemical properties and reactivity. By examining the electron configuration, we can determine the distribution of electrons in different energy levels and orbitals. Iron, with an atomic number of 26, has an electron configuration of [Ar] 3d6 4s2. This configuration indicates that iron has two electrons in its outermost energy level, making it a transition metal. When iron loses two electrons to form Fe2+, its electron configuration becomes [Ar] 3d6. On the other hand, when iron loses three electrons to form Fe3+, its electron configuration becomes [Ar] 3d5. These changes in electron configuration result in different chemical properties and reactivity for each ion. Overall, understanding the electron configuration of iron and its ions is crucial in comprehending their behavior in chemical reactions and their role in various biological processes.

Frequently Asked Questions

What is the electron configuration of Fe (Iron)?

The electron configuration of Fe (Iron) is [Ar] 4s2 3d6. This means that Iron has 2 electrons in its 4s orbital and 6 electrons in its 3d orbital, following the Argon (Ar) core.

How does the electron configuration change for Fe2+ and Fe3+ ions?

The electron configuration for Fe2+ is [Ar] 3d6 4s0 and for Fe3+ is [Ar] 3d5 4s0. This change occurs because the Fe2+ ion has lost 2 electrons and the Fe3+ ion has lost 3 electrons from the neutral Iron atom.

What is the subshell electron configuration?

Subshell electron configuration refers to the distribution of electrons in the subshells of an atom. For instance, in the case of Iron (Fe), the subshell electron configuration is 4s2 3d6.

What is the condensed electron configuration?

The condensed electron configuration is a simplified version of the electron configuration where the core electrons are represented by the symbol of the previous noble gas in the periodic table. For Iron (Fe), the condensed electron configuration is [Ar] 4s2 3d6.

How many electrons does Fe+4 have and what is its electron configuration?

Fe+4, or Iron (IV), has lost 4 electrons, so it has 22 electrons. Its electron configuration is [Ar] 3d4.

What is the electron configuration for the Fe3+ ion?

The electron configuration for the Fe3+ ion is [Ar] 3d5 4s0. This is because the Fe3+ ion has lost 3 electrons, 2 from the 4s orbital and 1 from the 3d orbital.

What is the difference between Fe2 and Fe3 in terms of electron configuration?

The difference between Fe2 and Fe3 lies in the number of electrons each has lost from the neutral Iron atom. Fe2+ has lost 2 electrons, resulting in the electron configuration [Ar] 3d6 4s0, while Fe3+ has lost 3 electrons, resulting in the electron configuration [Ar] 3d5 4s0.

What is the state electron configuration?

The state electron configuration refers to the electron configuration of an atom in a specific state. For example, the state electron configuration of Iron (Fe) in its ground state is [Ar] 4s2 3d6.

What is the abbreviated electron configuration?

The abbreviated electron configuration is another term for the condensed electron configuration. It provides a shortened version of the electron configuration by representing the core electrons with the symbol of the previous noble gas in the periodic table.

What is the gas electron configuration?

The gas electron configuration refers to the electron configuration of an atom in its gaseous state. For Iron (Fe), the gas electron configuration is the same as its ground state configuration, which is [Ar] 4s2 3d6.

Also Read:

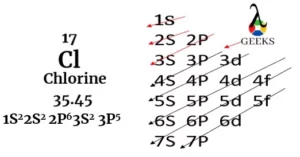

- Chlorine electron configuration

- Cadmium electron configuration

- Cerium electron configuration

- Vanadium electron configuration

- Holmium electron configuration

- Samarium electron configuration

- Tin electron configuration

- Calcium electron configuration

- Gd3 electron configuration

- Hassium electron configuration