The saturated suction temperature is an important concept in the field of refrigeration and air conditioning. It refers to the temperature at which the refrigerant vaporizes completely in the evaporator coil. This temperature is crucial because it determines the efficiency and performance of the cooling system. By maintaining the correct saturated suction temperature, the system can effectively remove heat from the desired space. Understanding the saturated suction temperature is essential for technicians and engineers involved in designing, installing, and maintaining refrigeration and air conditioning systems. In this article, we will explore the significance of saturated suction temperature and its impact on system performance. We will also discuss the factors that affect the saturated suction temperature and how it can be controlled to optimize system efficiency. So, let’s dive in and uncover the world of saturated suction temperature in refrigeration and air conditioning systems.

Key Takeaways

- Saturated suction temperature refers to the temperature at which the refrigerant vaporizes completely in the evaporator coil.

- It is an important parameter in refrigeration systems as it affects the cooling capacity and efficiency.

- The saturated suction temperature is determined by the pressure and the refrigerant being used.

- Proper monitoring and control of the saturated suction temperature is crucial for maintaining optimal system performance.

- Deviations from the desired saturated suction temperature can indicate issues such as low refrigerant charge or improper airflow.

Saturated Suction Temperature

The saturated suction temperature is a crucial parameter in refrigeration systems that plays a significant role in determining various key parameters. In this section, we will explore the definition and concept of saturated suction temperature, its relationship with system pressure, and its role in determining important parameters of a refrigeration system.

Definition and Concept

The saturated suction temperature refers to the temperature at which the refrigerant vaporizes completely in the evaporator coil of a refrigeration system. It is the temperature at which the refrigerant changes from a liquid state to a vapor state. This temperature is directly related to the pressure at which the refrigerant is maintained in the evaporator coil.

Relationship between System Pressure and Saturation Temperature

The saturated suction temperature is closely related to the system pressure in a refrigeration system. As the pressure increases, the saturation temperature also increases, and vice versa. This relationship is governed by the pressure-temperature relationship of the refrigerant being used.

For example, if we consider a refrigerant with a low-pressure range, such as R-134a, an increase in system pressure will result in an increase in the saturated suction temperature. On the other hand, refrigerants with a high-pressure range, like R-410A, will exhibit a similar relationship between pressure and saturation temperature.

Role of Saturated Suction Temperature in Determining Key Parameters of a Refrigeration System

The saturated suction temperature plays a crucial role in determining various key parameters of a refrigeration system. Let’s explore some of these parameters:

-

Superheat: The saturated suction temperature helps determine the superheat of the refrigerant vapor leaving the evaporator coil. Superheat refers to the temperature rise of the refrigerant vapor above its saturation temperature. It is an important parameter that ensures the complete evaporation of the refrigerant before it enters the compressor.

-

Subcooling: The saturated suction temperature also influences the subcooling of the liquid refrigerant leaving the condenser. Subcooling refers to the temperature drop of the liquid refrigerant below its saturation temperature. It helps improve the efficiency of the refrigeration system by ensuring that the liquid refrigerant is at a lower temperature than the surrounding environment.

-

Compressor Efficiency: The saturated suction temperature directly affects the efficiency of the compressor. A higher saturated suction temperature can lead to decreased compressor efficiency due to increased power consumption and reduced cooling capacity. On the other hand, maintaining a lower saturated suction temperature can improve the overall efficiency of the system.

-

Heat Transfer: The saturated suction temperature influences the heat transfer process within the evaporator coil. By maintaining an optimal saturated suction temperature, the refrigeration system can efficiently absorb heat from the surroundings and provide effective cooling.

-

Condensing Temperature: The saturated suction temperature indirectly affects the condensing temperature of the refrigerant. A higher saturated suction temperature can result in a higher condensing temperature, which may impact the overall performance and efficiency of the system.

-

Evaporating Temperature: The saturated suction temperature is an indicator of the evaporating temperature, which is the temperature at which the refrigerant absorbs heat in the evaporator coil. By controlling the saturated suction temperature, the system can maintain the desired evaporating temperature for efficient cooling.

In conclusion, the saturated suction temperature is a critical parameter in refrigeration systems that influences various key parameters such as superheat, subcooling, compressor efficiency, heat transfer, condensing temperature, and evaporating temperature. By understanding and controlling the saturated suction temperature, it is possible to optimize the performance and efficiency of a refrigeration system.

Suction Temperature

The suction temperature plays a crucial role in the efficient operation of a refrigeration system. It is important to understand the definition and significance of suction temperature in order to optimize the performance of the system. Additionally, the ideal temperature in relation to saturation temperature and system pressure is a key factor to consider. Let’s delve deeper into these aspects.

Definition and Significance in a Refrigeration System

The suction temperature refers to the temperature of the refrigerant vapor as it enters the compressor’s suction line. It is a critical parameter that directly affects the performance and efficiency of the entire refrigeration system.

In a refrigeration cycle, the compressor’s main function is to compress the refrigerant vapor, raising its pressure and temperature. The suction temperature determines the state of the refrigerant entering the compressor. If the suction temperature is too high, it can lead to several issues, including decreased compressor efficiency, reduced cooling capacity, and potential damage to the compressor itself.

By monitoring and controlling the suction temperature, technicians can ensure that the refrigeration system operates optimally. This involves maintaining the suction temperature within a specific range, which is determined by factors such as the type of refrigerant used and the desired cooling requirements.

Ideal Temperature in Relation to Saturation Temperature and System Pressure

The ideal suction temperature is closely related to the saturation temperature and the system pressure. Saturation temperature refers to the temperature at which the refrigerant changes state from a liquid to a vapor or vice versa, while system pressure is the pressure at which the refrigerant operates within the system.

To understand the ideal suction temperature, it is important to consider the relationship between saturation temperature and system pressure. As the system pressure increases, the saturation temperature also rises. Conversely, as the system pressure decreases, the saturation temperature decreases as well.

The ideal suction temperature should be slightly lower than the saturation temperature at the corresponding system pressure. This temperature difference, known as superheat, ensures that only vapor enters the compressor, preventing any liquid refrigerant from causing damage. Superheat also helps to improve the efficiency of the heat transfer process within the evaporator coil.

On the other hand, if the suction temperature is too low, it can lead to a phenomenon called subcooling, where the refrigerant exists in a liquid state below its saturation temperature. Subcooling can negatively impact the overall efficiency of the system and result in poor heat transfer.

To calculate the ideal suction temperature, technicians use pressure-temperature charts specific to the refrigerant being used. These charts indicate the saturation temperature at various system pressures, allowing technicians to determine the appropriate suction temperature for optimal system performance.

In conclusion, the suction temperature is a critical parameter in a refrigeration system. By understanding its definition and significance, as well as its relation to saturation temperature and system pressure, technicians can ensure the system operates efficiently and effectively. Monitoring and controlling the suction temperature within the ideal range is essential for maintaining the overall performance and longevity of the refrigeration system.

Low Saturated Suction Temperature

A low saturated suction temperature in a refrigeration system can have various causes and implications. Understanding the importance of the degree of superheat in the refrigerant and the desired degree of superheat at the evaporator outlet and compressor suction is crucial for maintaining optimal system performance.

Causes and Implications of Low Suction Temperature

There are several factors that can contribute to a low saturated suction temperature in a refrigeration system. Some common causes include:

-

Insufficient refrigerant charge: If the system is undercharged with refrigerant, it can result in a low suction temperature. This occurs because there is not enough refrigerant flowing through the evaporator coil to absorb heat effectively.

-

Refrigerant restrictions: Any obstructions or restrictions in the refrigerant lines, such as clogged filters or blocked expansion valves, can lead to a decrease in the suction temperature. These restrictions limit the flow of refrigerant and reduce the system’s ability to transfer heat efficiently.

-

Inadequate airflow: Insufficient airflow across the evaporator coil can cause a decrease in the suction temperature. This can be caused by dirty or blocked air filters, malfunctioning fans, or improper ductwork design.

-

Faulty expansion valve: A malfunctioning or improperly adjusted expansion valve can result in a low suction temperature. If the valve is not allowing enough refrigerant to enter the evaporator coil, the suction temperature will be lower than desired.

A low saturated suction temperature can have several implications on the performance of a refrigeration system:

-

Reduced cooling capacity: A lower suction temperature means that the evaporator coil is not absorbing as much heat as it should. This results in reduced cooling capacity, leading to inadequate temperature control and potential spoilage of perishable goods.

-

Decreased compressor efficiency: The compressor is designed to operate within a specific range of temperatures. When the suction temperature is too low, the compressor may experience issues such as liquid refrigerant entering the compressor, which can cause damage and decrease its efficiency.

-

Poor heat transfer: With a low suction temperature, the temperature difference between the refrigerant and the surrounding air or water is reduced. This can result in poor heat transfer, making it harder for the system to remove heat from the conditioned space.

Importance of Degree of Superheat in Refrigerant

The degree of superheat in the refrigerant is a critical parameter that indicates the amount of heat absorbed by the refrigerant in the evaporator coil. It is defined as the temperature of the refrigerant vapor above its saturation temperature at a given pressure.

Maintaining the correct degree of superheat is essential for the efficient operation of a refrigeration system. Here’s why:

-

Prevents liquid refrigerant from entering the compressor: If the refrigerant entering the compressor contains liquid droplets, it can cause damage to the compressor and reduce its efficiency. By ensuring an adequate degree of superheat, the refrigerant is fully vaporized before entering the compressor, minimizing the risk of liquid carryover.

-

Maximizes heat transfer: The degree of superheat affects the efficiency of heat transfer in the evaporator coil. A proper degree of superheat ensures that the refrigerant absorbs enough heat to vaporize completely, optimizing the cooling capacity of the system.

Desired Degree of Superheat at Evaporator Outlet and Compressor Suction

The desired degree of superheat at the evaporator outlet and compressor suction depends on various factors, including the type of refrigerant, the design of the system, and the operating conditions. However, there are general guidelines to follow:

-

Evaporator outlet: The desired degree of superheat at the evaporator outlet typically ranges between 5 to 20 degrees Fahrenheit (2.8 to 11.1 degrees Celsius). This range ensures that the refrigerant is fully vaporized before entering the compressor, preventing liquid carryover.

-

Compressor suction: The desired degree of superheat at the compressor suction is usually higher than at the evaporator outlet. It is recommended to have a superheat of around 10 to 30 degrees Fahrenheit (5.6 to 16.7 degrees Celsius) at the compressor suction. This higher superheat helps to protect the compressor from any potential liquid refrigerant damage.

Maintaining the desired degree of superheat requires careful monitoring and adjustment of the refrigeration system. Regular inspections, proper refrigerant charging, and ensuring adequate airflow are essential for achieving and maintaining the optimal superheat levels.

In conclusion, a low saturated suction temperature can have various causes and implications in a refrigeration system. Understanding the importance of the degree of superheat and maintaining the desired superheat levels at the evaporator outlet and compressor suction are crucial for ensuring efficient system performance and preventing potential damage to the compressor.

Calculation of Saturated Suction Temperature

The saturated suction temperature is an important parameter in refrigeration systems as it directly affects the performance and efficiency of the system. There are different methods to calculate the saturated suction temperature, including the Clausius-Clapeyron equation and the use of a pressure-temperature equilibrium chart.

Clausius-Clapeyron Equation for Determining Saturated Suction Temperature

The Clausius-Clapeyron equation is a fundamental equation in thermodynamics that relates the temperature and pressure of a substance during a phase change. In the case of a refrigeration system, it can be used to determine the saturated suction temperature.

The equation states that the natural logarithm of the ratio of the vapor pressure at two different temperatures is equal to the enthalpy of vaporization divided by the gas constant, multiplied by the difference in inverse temperatures. Mathematically, it can be expressed as:

ln(P2/P1) = (ΔHvap/R) * (1/T1 – 1/T2)

Where:

– P1 and P2 are the vapor pressures at temperatures T1 and T2, respectively.

– ΔHvap is the enthalpy of vaporization.

– R is the gas constant.

– T1 and T2 are the temperatures at which the vapor pressures are measured.

By rearranging the equation, we can solve for the saturated suction temperature:

T2 = (1 / ((ln(P2/P1) * R / ΔHvap) + (1 / T1)))

This equation allows us to calculate the saturated suction temperature based on the known vapor pressures at two different temperatures.

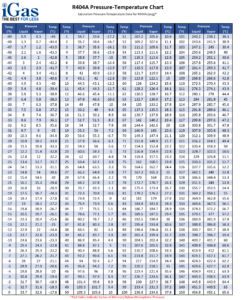

Use of Pressure-Temperature Equilibrium Chart for Measurement

Another method to determine the saturated suction temperature is by using a pressure-temperature equilibrium chart. This chart provides a graphical representation of the relationship between the pressure and temperature of a refrigerant at its saturation point.

To use the chart, you need to know the pressure at the suction line of the refrigeration system. Locate this pressure on the chart and follow the corresponding line until it intersects with the saturation curve. The temperature at this intersection point is the saturated suction temperature.

The pressure-temperature equilibrium chart is a useful tool for quickly determining the saturated suction temperature without the need for complex calculations. It is commonly used by technicians and engineers in the field to troubleshoot refrigeration systems and ensure optimal performance.

In conclusion, the saturated suction temperature is a critical parameter in refrigeration systems. It can be calculated using the Clausius-Clapeyron equation or determined using a pressure-temperature equilibrium chart. Both methods provide accurate results and are widely used in the industry. By accurately measuring and controlling the saturated suction temperature, refrigeration systems can operate efficiently and effectively.

High Saturated Suction Temperature

When it comes to refrigeration systems, maintaining the right temperature is crucial for optimal performance. One important factor to consider is the saturated suction temperature. This refers to the temperature at which the refrigerant in the evaporator coil is completely vaporized, ready to be compressed by the compressor. In this section, we will explore the causes and consequences of high saturated suction temperature, the disadvantages of a higher degree of superheat in the refrigeration cycle, and the impact on compressor performance and system degradation.

Causes and Consequences of High Saturated Suction Temperature

A high saturated suction temperature can be caused by various factors, including improper refrigerant charge, inadequate airflow across the evaporator coil, or a malfunctioning expansion valve. When the suction temperature is higher than normal, it can have several consequences on the refrigeration system.

Firstly, a high saturated suction temperature can lead to a decrease in system efficiency. This is because the compressor has to work harder to compress the refrigerant vapor, resulting in increased energy consumption. Additionally, the higher temperature can cause the compressor to overheat, leading to reduced compressor lifespan and potential breakdowns.

Moreover, high saturated suction temperature can negatively impact the heat transfer process. When the refrigerant vapor exiting the evaporator coil is not fully vaporized, it can carry liquid droplets with it. These liquid droplets can cause issues such as reduced heat transfer efficiency, increased pressure drop, and potential damage to the compressor.

Disadvantages of a Higher Degree of Superheat in the Refrigeration Cycle

In a refrigeration cycle, superheat refers to the temperature of the refrigerant vapor above its saturation point. While a certain degree of superheat is necessary for proper refrigeration system operation, a higher degree of superheat can have disadvantages.

One disadvantage is reduced compressor efficiency. When the degree of superheat is too high, the compressor has to work harder to compress the vapor, resulting in increased energy consumption. This not only leads to higher operating costs but also puts additional strain on the compressor, potentially reducing its lifespan.

Another disadvantage is decreased cooling capacity. When the refrigerant vapor has a higher degree of superheat, it carries less heat energy. As a result, the evaporator coil may not be able to remove as much heat from the conditioned space, leading to reduced cooling capacity and potentially inadequate temperature control.

Impact on Compressor Performance and System Degradation

High saturated suction temperature can have a significant impact on compressor performance and overall system degradation. The compressor plays a crucial role in the refrigeration cycle by compressing the refrigerant vapor and increasing its pressure.

When the saturated suction temperature is high, the compressor has to work harder to compress the vapor. This increased workload can lead to higher energy consumption, reduced compressor efficiency, and increased wear and tear on the compressor components. Over time, this can result in decreased performance, increased maintenance requirements, and potentially premature compressor failure.

Furthermore, high saturated suction temperature can contribute to system degradation. The increased temperature can cause the refrigerant to break down and form acids, which can corrode the compressor and other system components. This corrosion can lead to refrigerant leaks, reduced system efficiency, and costly repairs.

In conclusion, maintaining the right saturated suction temperature is crucial for the optimal performance and longevity of a refrigeration system. A high saturated suction temperature can have various causes and consequences, including decreased system efficiency, reduced compressor lifespan, and potential system degradation. It is important to regularly monitor and control the saturated suction temperature to ensure the smooth operation of the refrigeration system.

Saturated Suction Temperature of Specific Refrigerants

The saturated suction temperature is an important parameter to consider when working with refrigeration systems. It refers to the temperature at which the refrigerant vaporizes completely in the evaporator coil of the system. Understanding the saturated suction temperature is crucial for maintaining the efficiency and performance of the refrigeration system.

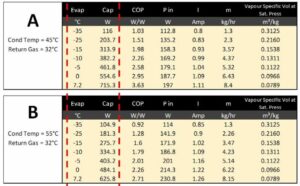

Saturated Suction Temperature Chart for R404a

R404a is a commonly used refrigerant in commercial refrigeration systems. It is a blend of three refrigerants: R125, R143a, and R134a. To determine the saturated suction temperature for R404a, we can refer to a chart that provides the relationship between the pressure and temperature of the refrigerant.

The chart indicates that at a certain pressure, the saturated suction temperature of R404a will be a specific value. This information is useful for technicians and engineers who need to calculate the operating conditions of the system and ensure it is within the recommended range.

Here is an example of a saturated suction temperature chart for R404a:

| Pressure (psig) | Saturated Suction Temperature (°F) |

|---|---|

| 10 | -20 |

| 20 | -10 |

| 30 | 0 |

| 40 | 10 |

| 50 | 20 |

By referring to this chart, one can determine the saturated suction temperature of R404a based on the pressure reading in the system. This information is crucial for maintaining the proper operation of the refrigeration system and preventing any potential issues.

Saturated Suction Temperature for R134a and R410a

Apart from R404a, there are other refrigerants commonly used in refrigeration systems, such as R134a and R410a. These refrigerants also have specific saturated suction temperatures at different pressures.

For R134a, the saturated suction temperature can range from -20°F to 40°F, depending on the pressure in the system. It is important to note that as the pressure increases, the saturated suction temperature also increases. This relationship is crucial for maintaining the proper operation of the refrigeration system and ensuring efficient heat transfer in the evaporator coil.

Similarly, for R410a, the saturated suction temperature can range from -40°F to 50°F, depending on the pressure. It is important to monitor and control the saturated suction temperature to prevent any issues with the refrigeration system, such as insufficient cooling or compressor damage.

Understanding the saturated suction temperature of specific refrigerants is essential for maintaining the efficiency and performance of refrigeration systems. By monitoring and controlling this parameter, technicians and engineers can ensure optimal heat transfer, prevent compressor damage, and maintain the desired cooling capacity of the system.

Measurement and Calculation of Saturated Suction Temperature

The saturated suction temperature is a crucial parameter in refrigeration systems as it directly affects the efficiency and performance of the system. By accurately measuring and calculating the saturated suction temperature, technicians can ensure optimal operation and prevent any potential issues. In this section, we will explore the tools and methods used for measuring suction pressure and how PT charts can be utilized to determine the saturated temperature.

Tools and Methods for Measuring Suction Pressure

To measure the suction pressure accurately, technicians rely on specialized tools and methods. These tools enable them to obtain precise readings, allowing for accurate calculation of the saturated suction temperature. Here are some commonly used tools and methods:

-

Pressure Gauges: Pressure gauges are essential tools for measuring suction pressure. They are connected to the suction line of the refrigeration system and provide a reading in units such as psi or bar. Technicians can use these readings to calculate the saturated suction temperature.

-

Manifold Gauge Set: A manifold gauge set is a combination of pressure gauges, valves, and hoses. It allows technicians to measure both the suction pressure and the discharge pressure simultaneously. By comparing these readings, technicians can determine the temperature difference and calculate the saturated suction temperature.

-

Digital Thermometer: A digital thermometer is used to measure the temperature of the suction line. By placing the thermometer probe on the suction line, technicians can obtain an accurate reading of the suction line temperature. This reading, along with the suction pressure, can be used to calculate the saturated suction temperature.

Utilizing PT Charts to Determine Saturated Temperature

PT charts, also known as pressure-temperature charts, are valuable references for determining the saturated temperature of a refrigerant at a given pressure. These charts provide a graphical representation of the relationship between pressure and temperature for a specific refrigerant. Here’s how technicians can use PT charts to determine the saturated suction temperature:

-

Identify the Refrigerant: First, technicians need to identify the refrigerant used in the system. Each refrigerant has its own unique PT chart, so it’s crucial to ensure the correct chart is being used.

-

Find the Suction Pressure: Using the pressure gauge or manifold gauge set, technicians can determine the suction pressure of the refrigeration system. They can then locate this pressure value on the PT chart.

-

Read the Saturated Temperature: Once the suction pressure is identified on the PT chart, technicians can read the corresponding saturated temperature. This temperature indicates the point at which the refrigerant is fully vaporized and ready to enter the compressor.

By utilizing PT charts and accurately measuring the suction pressure, technicians can determine the saturated suction temperature with precision. This information is vital for maintaining the efficiency and performance of the refrigeration system.

In conclusion, the measurement and calculation of the saturated suction temperature are critical for ensuring the optimal operation of refrigeration systems. By using tools such as pressure gauges and digital thermometers, technicians can accurately measure the suction pressure and temperature. Additionally, PT charts provide a valuable reference for determining the saturated temperature based on the suction pressure. By incorporating these methods into their practices, technicians can effectively monitor and maintain the performance of refrigeration systems.

Vacuum Saturation Temperature

In refrigeration systems, the concept of vacuum saturation temperature plays a crucial role. Understanding this concept is essential for maintaining the efficiency and performance of the system. Let’s dive into an explanation of what vacuum saturation temperature is and its relevance in refrigeration systems.

Explanation and Relevance in Refrigeration Systems

The vacuum saturation temperature refers to the temperature at which a refrigerant becomes saturated and changes from a liquid to a vapor state. It is an important parameter used to calculate the performance of a refrigeration system, particularly in the suction line of the compressor.

When a refrigerant enters the evaporator coil of a refrigeration system, it absorbs heat from the surroundings and evaporates. As the refrigerant evaporates, its temperature rises until it reaches the vacuum saturation temperature. At this point, the refrigerant is fully saturated, meaning it has absorbed enough heat to completely vaporize.

The vacuum saturation temperature is crucial because it indicates the efficiency of the evaporator coil. If the suction temperature is too high, it may indicate that the evaporator coil is not absorbing enough heat from the surroundings. On the other hand, if the suction temperature is too low, it may indicate that the evaporator coil is absorbing too much heat, resulting in inefficient cooling.

By monitoring the vacuum saturation temperature, technicians can assess the performance of the evaporator coil and make necessary adjustments to optimize the system’s efficiency. It helps in maintaining the desired cooling capacity and preventing issues such as inadequate cooling or excessive energy consumption.

Moreover, the vacuum saturation temperature also affects the compressor’s operation. The compressor’s suction pressure is directly related to the saturation temperature. If the suction pressure is too high, it indicates that the compressor is working harder to compress the refrigerant. Conversely, if the suction pressure is too low, it may indicate that the compressor is not receiving enough refrigerant.

By monitoring and controlling the vacuum saturation temperature, technicians can ensure that the compressor operates within the desired range, maximizing its efficiency and lifespan. It also helps in preventing issues such as compressor overheating, which can lead to system breakdowns and costly repairs.

In summary, the vacuum saturation temperature is a critical parameter in refrigeration systems. It helps technicians assess the performance of the evaporator coil, optimize cooling efficiency, and ensure the compressor operates within the desired range. By monitoring this temperature, refrigeration systems can maintain their efficiency, prolong the lifespan of components, and provide reliable cooling.

Saturated Suction Temperature in Carrier Chiller

Application and Considerations in Carrier Chiller Systems

The saturated suction temperature plays a crucial role in the efficient operation of Carrier chiller systems. It is a key parameter that helps in determining the performance and reliability of the refrigeration system. In this section, we will explore the application and considerations of saturated suction temperature in Carrier chiller systems.

Importance of Saturated Suction Temperature

The saturated suction temperature refers to the temperature at which the refrigerant in the evaporator coil is completely vaporized. It is an essential parameter as it directly affects the efficiency and capacity of the chiller system. By maintaining the proper saturated suction temperature, the chiller can operate optimally, ensuring efficient heat transfer and cooling.

Calculating Saturated Suction Temperature

To calculate the saturated suction temperature, one needs to consider the refrigerant being used and the corresponding pressure at the suction side of the compressor. The pressure-temperature relationship of the refrigerant is crucial in determining the saturated suction temperature. By knowing the pressure, one can refer to the refrigerant’s pressure-temperature chart to find the corresponding temperature.

Indicating System Performance

The saturated suction temperature serves as an indicator of the system’s performance. If the saturated suction temperature is too high, it may indicate issues such as low refrigerant charge, insufficient airflow across the evaporator coil, or a dirty evaporator coil. On the other hand, if the saturated suction temperature is too low, it may suggest problems like overcharging of refrigerant or a restricted metering device.

Considerations for Optimal Performance

To ensure optimal performance of the Carrier chiller system, several considerations should be taken into account regarding the saturated suction temperature:

-

Refrigerant Selection: The choice of refrigerant can significantly impact the saturated suction temperature. Different refrigerants have varying pressure-temperature characteristics, which can affect the system’s overall performance.

-

Superheat and Subcooling: Proper superheat and subcooling levels are essential for maintaining the desired saturated suction temperature. Superheat refers to the temperature rise of the refrigerant vapor above its saturation temperature, while subcooling refers to the temperature drop of the refrigerant liquid below its saturation temperature.

-

Compressor Efficiency: The saturated suction temperature directly affects the compressor’s efficiency. Higher saturated suction temperatures can lead to reduced compressor efficiency, increased energy consumption, and potential compressor damage.

-

Heat Transfer: The saturated suction temperature affects the heat transfer process in the evaporator coil. By maintaining the correct saturated suction temperature, the chiller system can efficiently absorb heat from the cooling load.

-

Condensing Temperature: The saturated suction temperature is also related to the condensing temperature, which is the temperature at which the refrigerant rejects heat to the surroundings. Proper control of the condensing temperature is crucial for maintaining the desired saturated suction temperature.

In conclusion, the saturated suction temperature is a critical parameter in Carrier chiller systems. It helps in determining the system’s performance, efficiency, and reliability. By considering the application and various considerations mentioned above, one can ensure optimal operation and maximize the lifespan of the chiller system.

Saturated Suction Temperature in Ice Machines

The saturated suction temperature is a crucial factor that greatly impacts the performance of ice machines. By understanding its importance, we can optimize the efficiency and output of these machines. Let’s delve into the significance of saturated suction temperature and its impact on ice machine performance.

Importance and Impact on Ice Machine Performance

The saturated suction temperature refers to the temperature at which the refrigerant vaporizes in the evaporator coil of an ice machine. It plays a vital role in determining the overall efficiency and effectiveness of the refrigeration system.

When the refrigerant enters the evaporator coil, it undergoes a phase change from liquid to vapor. This process absorbs heat from the surrounding environment, causing the temperature to drop. The saturated suction temperature indicates the point at which the refrigerant is fully vaporized, ready to be compressed by the compressor.

Maintaining the correct saturated suction temperature is crucial for several reasons:

-

Optimal Heat Transfer: The saturated suction temperature directly affects the heat transfer process in the evaporator coil. If the temperature is too high, the refrigerant may not absorb enough heat from the surroundings, leading to inefficient cooling. On the other hand, if the temperature is too low, the refrigerant may become superheated, reducing the overall cooling capacity.

-

Compressor Efficiency: The compressor plays a vital role in the refrigeration cycle, and its efficiency is greatly influenced by the saturated suction temperature. If the temperature is too high, the compressor has to work harder to compress the refrigerant, resulting in increased energy consumption and reduced compressor lifespan. Conversely, if the temperature is too low, the compressor may experience liquid refrigerant floodback, leading to potential damage.

-

Ice Production: The saturated suction temperature directly affects the rate at which ice is produced in ice machines. By maintaining the optimal temperature, ice production can be maximized, ensuring a steady supply of ice for various applications, such as food service establishments, healthcare facilities, and more.

To determine the saturated suction temperature, it is essential to monitor the refrigerant pressure at the evaporator outlet. By using pressure-temperature charts or digital gauges, one can calculate the corresponding temperature. This information helps in adjusting the system parameters to achieve the desired saturated suction temperature.

In conclusion, the saturated suction temperature plays a critical role in ice machine performance. By maintaining the optimal temperature, we can enhance heat transfer efficiency, improve compressor performance, and maximize ice production. Understanding and monitoring this temperature is vital for ensuring the smooth operation and longevity of ice machines.

Conclusion

In conclusion, the saturated suction temperature is a crucial concept in the field of refrigeration and air conditioning. It refers to the temperature at which the refrigerant vaporizes completely in the evaporator coil. By maintaining the correct saturated suction temperature, technicians can ensure optimal performance and efficiency of the system. It is influenced by factors such as the refrigerant type, pressure, and superheat. Monitoring and controlling the saturated suction temperature is essential for preventing issues like compressor overheating, poor cooling capacity, and increased energy consumption. By understanding the significance of saturated suction temperature and its impact on system operation, technicians can make informed decisions to maintain and troubleshoot refrigeration and air conditioning systems effectively.

Frequently Asked Questions

What is saturated condensing temperature?

Saturated condensing temperature refers to the temperature at which the refrigerant in the condenser coil changes from a vapor to a saturated mixture of vapor and liquid.

What is saturated suction temperature?

Saturated suction temperature is the temperature at which the refrigerant in the evaporator coil changes from a saturated mixture of vapor and liquid to a vapor only.

What does low saturated suction temperature mean?

A low saturated suction temperature indicates that the refrigerant entering the compressor is colder than expected. This can be caused by issues such as low refrigerant charge, restricted airflow, or a malfunctioning expansion valve.

What causes high saturated suction temperature?

High saturated suction temperature can be caused by factors such as high refrigerant charge, restricted airflow, dirty evaporator coil, or a malfunctioning expansion valve.

How to calculate saturated suction temperature?

Saturated suction temperature can be calculated using the temperature-pressure relationship of the refrigerant. By knowing the saturated suction pressure, you can use a refrigerant pressure-temperature chart to determine the corresponding temperature.

How to measure saturated suction temperature?

Saturated suction temperature can be measured using a thermometer or a temperature probe placed at the suction line of the refrigeration system, near the evaporator coil.

What is superheat?

Superheat is the temperature difference between the actual temperature of the refrigerant vapor and its saturation temperature at a given pressure. It indicates the amount of heat added to the refrigerant vapor after it has fully evaporated.

What is subcooling?

Subcooling is the temperature difference between the actual temperature of the refrigerant liquid and its saturation temperature at a given pressure. It indicates the amount of heat removed from the refrigerant liquid after it has fully condensed.

What is compressor efficiency?

Compressor efficiency is a measure of how effectively a compressor converts electrical energy into mechanical energy to compress the refrigerant. It is typically expressed as a percentage and is influenced by factors such as compressor design, operating conditions, and refrigerant properties.

What is heat transfer?

Heat transfer is the process of transferring thermal energy between two objects or systems. In the context of refrigeration systems, heat transfer occurs between the refrigerant and the surrounding environment, such as the evaporator coil absorbing heat from the space being cooled and the condenser coil releasing heat to the outside environment.

What is condensing temperature?

Condensing temperature is the temperature at which the refrigerant in the condenser coil changes from a vapor to a liquid state. It is determined by the pressure at which the refrigerant is condensed and is influenced by factors such as ambient temperature and the efficiency of the condenser.

I am Sangeeta Das. I have completed my Masters in Mechanical Engineering with specialization in I.C Engine and Automobiles. I have around ten years of experience encompassing industry and academia. My area of interest includes I.C. Engines, Aerodynamics and Fluid Mechanics. You can reach me at