Content : Dual Cycle

What is Dual cycle?

Dual Combustion Cycle | Mixed cycle | Sabathe cycle

Dual cycle is a combination of constant volume Otto cycle and constant pressure diesel cycle. Heat addition takes place in two parts in this cycle. Partial heat addition takes place at constant volume similar to Otto cycle while the remaining Partial heat addition takes place at constant pressure similar to diesel cycle. The significance of such method of heat addition is it gives more time to fuel for complete combustion.

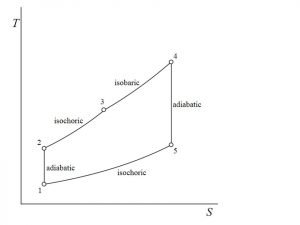

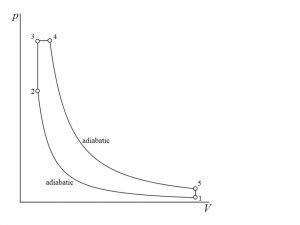

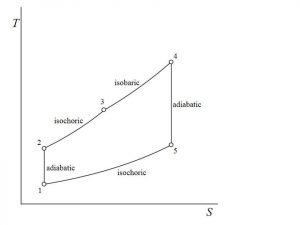

Dual cycle P-V Diagram | Dual cycle T-S Diagram

The dual cycle comprises of following operations:

- Process 1-2 follows the reversible adiabatic or Isentropic compression

- In Process 2-3 constant volume partial heat Addition takes place

- In Process 3-4 constant pressure partial heat Addition takes place

- Process 4-5 follows reversible adiabatic or isentropic expansion.

- In Process 5-1 constant volume heat rejection takes place

Image credit :Shoji Yamauchi, T-S Chart of Sabathe Cycle, CC BY-SA 4.0

Image credit : Shoji Yamauchi, P-V Chart of Sabathe Cycle, CC BY-SA 4.0

Dual Cycle efficiency | Dual Cycle Thermal efficiency

The efficiency of dual cycle is given by

![Rendered by QuickLaTeX.com \\eta_{dual}=1-\\frac{1}{r_k^{\\gamma -1}}[\\frac{r_pr_c^\\gamma -1}{(r_p-1)+r_p\\gamma (r_c-1)}]](https://lambdageeks.com/wp-content/ql-cache/quicklatex.com-ef5d62cb8110d7b8f13b61f35836bb06_l3.png)

Where, rp = Pressure ratio = P3/P2

rk = compression ratio = V1/V2

rc = cutoff ratio = V4 /V3

re = expansion ratio = V5/V4

When rc = 1, The cycle becomes Otto cycle

rp = 1, the cycle becomes diesel cycle.

Dual cycle P-V and T-S diagram

Image credit : Shoji Yamauchi, P-V Chart of Sabathe Cycle, CC BY-SA 4.0

Image credit :Shoji Yamauchi, T-S Chart of Sabathe Cycle, CC BY-SA 4.0

Air standard dual cycle | Dual cycle efficiency derivation

The dual cycle comprises of following operations:

- Process 1-2 follows the reversible adiabatic or Isentropic compression

- In Process 2-3 constant volume partial heat Addition takes place

- In Process 3-4 constant pressure partial heat Addition takes place

- Process 4-5 follows reversible adiabatic or isentropic expansion.

- In Process 5-1 constant volume heat rejection takes place

Total Heat supplied is given by

![]()

Where Heat supplied at constant volume

![]()

Where Heat supplied at constant pressure

![]()

Heat rejected at constant volume is given by

![]()

The efficiency of dual cycle is given by

![]()

![Rendered by QuickLaTeX.com \\\\\\eta=1-\\frac{(T_5-T_1)}{([T_3-T_2 ]+\\gamma[T_4-T_3])}\\\\\\\\ \\eta_{dual}=1-\\frac{1}{r_k^{\\gamma -1}}[\\frac{r_pr_c^\\gamma -1}{(r_p-1)+r_p\\gamma (r_c-1)}]](https://lambdageeks.com/wp-content/ql-cache/quicklatex.com-8d7a6e6fd77001105b5968b92751f278_l3.png)

Where, rp = Pressure ratio = P3/P2

rk = compression ratio = V1/V2

rc = cutoff ratio = V4 /V3

re = expansion ratio = V5/V4

When rc = 1, the cycle becomes Otto cycle

rp = 1, the cycle becomes diesel cycle.

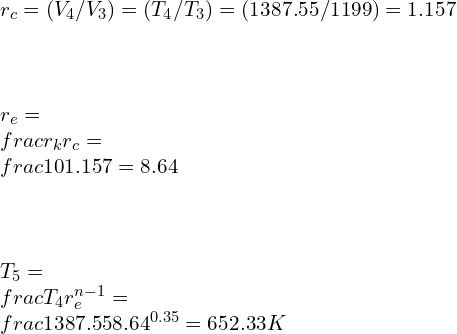

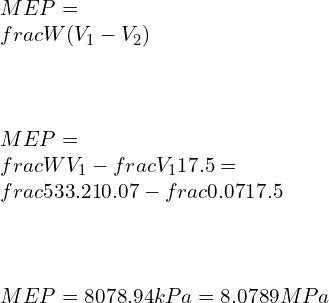

Mean effective pressure of dual cycle

The mean effective pressure of dual cycle is given by

![Rendered by QuickLaTeX.com M.E.P=\\frac{(P_1 [\\gamma r_p r_k^\\gamma (r_c-1)+r_k^\\gamma (r_p-1)-r_k (r_p r_c^\\gamma-1) ] )}{(\\gamma-1)(r_k-1) }](https://lambdageeks.com/wp-content/ql-cache/quicklatex.com-b84ee279a3d25c3e77b699126299c702_l3.png)

Where, rp = Pressure ratio = P3/P2

rk = compression ratio = V1/V2

rc = cutoff ratio = V4 /V3

re = expansion ratio = V5/V4

Otto Diesel Dual Cycle Diagram

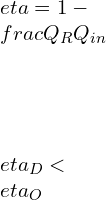

Comparison between Otto, diesel and dual cycle

Case 1: For similar compression ratio and similar heat i/p this relationship will be

[Qin]otto = [Qin]Diesel.

[QR]otto< [QR]Diesel.

In this case of same compression ratio and equal heat input it will be

Case 2: In this case of, same compression ratio and same heat-rejection, this relationship will be

[Qin]otto> [Qin]Diesel.

[QR]otto= [QR]Diesel.

In this case of, same compression ratio and same heat-rejection.

Case 3: In this case of, same Maximum Temperature and same heat-rejection.

[QR]otto= [QR]Diesel

[Qin]Diesel>[Qin]otto

For same Maximum Temperature and same heat rejection

Dual fuel engine cycle | Mixed dual cycle

Dual Cycle Engine

Dual fuel engine works primarily on diesel cycle. The gaseous fuel [Natural gas] is introduced into the engine’s intake system through a supercharger at higher atmospheric pressure.

During the suction stroke, the leaner air-to-fuel ratio [air-to-natural gas mixture] is drawn into the cylinder, following the Otto cycle just as used in a spark-ignited engine. A small charge of pilot fuel is injected near the Top Dead Center and similar to CI engine it ignites near the end of the compression stroke, causing the secondary gas to burn. The combustion takes place smoothly and rapidly.

In dual-fuel engine pilot fuel and secondary fuel both burn simultaneously in a compression ignition engine. After the compression of secondary fuel at the suction stroke pilot fuel is used as a source of ignition.

The operating cost of this engine is lower than that of conventional diesel engine without compromising in delivery power, high torque and transient response.

Dual cycle application

- Dual cycle is widely used for small propulsion engines and portable heavy duty machinery like drilling machines by companies like Cummins etc. The major reason of dual cycle being used in mobile equipment’s is it provides high power to mass ratio in comparison with Otto and diesel cycle.

- They have wide range of application in aircraft and ships. Dual cycle engine are also called marine engine.

Advantage of dual cycle

- Higher heat yield – methane has the highest thermal output per unit mass of fuel, at 50,500kJ/kg methane burned compared to 44,390kJ heat/kg petrol burned or 43,896kJ heat/kg diesel burned. Many dual-combustion engines use natural gas whose primary content is methane as starter fuels because of its higher heat output.

- With a dual fuel combustion engine, two fuels must be purchased instead of one. This can help when the ship is low on both fuels, and the re-fueling location lacks one of the two fuels the engine takes in.

- A potential balance between clean fuel and economical storage – natural gas needs higher storage pressure and volume but offers better combustion efficiency. Diesel is easier to store (it’s a liquid oil) but does not burn as quickly for the same temperature and pressure as the other fuels. With a dual combustion engine, one can start the diesel engine then switch to natural gas when the combustion space is hot enough.

Dual Cycle problems and solutions

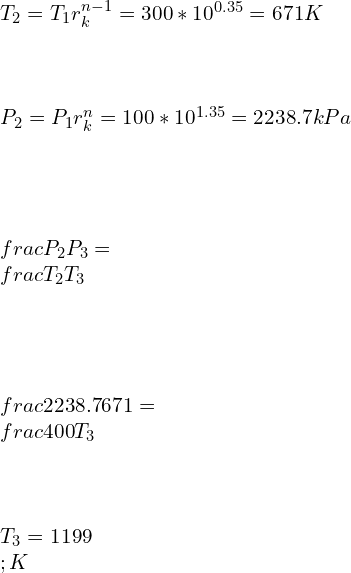

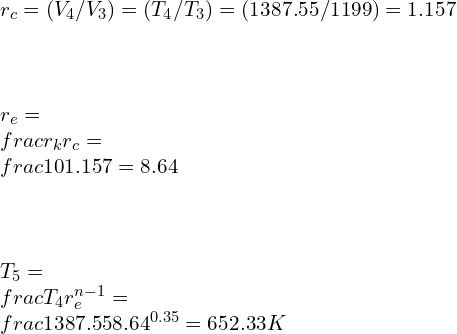

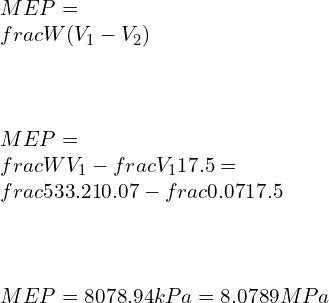

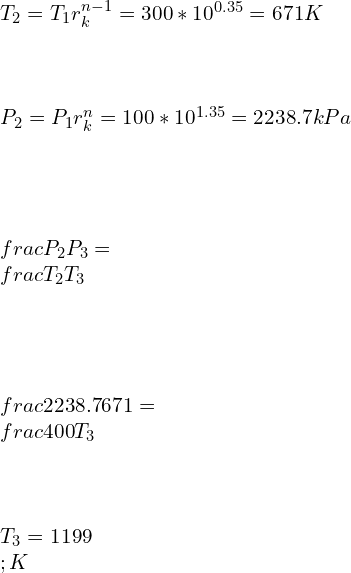

A C.I engine has a compression ratio of 10. The heat liberated at constant volume is 2/3 of total Heat while the remaining is liberated at constant pressure. The initial pressure and temperature is 1 bar and 27oC. Maximum cycle pressure is 40 bars. Find temperature at the end of compression and expansion. [PV1.35 = C, ϒ = 1.4]

Solution: rk = 10, P1 = 1 bar = 100 kPa, T1=27 C = 300K, P3 = P4 = 40 bar, PV1.35 = C, ϒ = 1.4

Heat input at constant volume

![Rendered by QuickLaTeX.com \\\\Q_v=C_v [T_3-T_2 ]=0.718*[1199-671]=379kJ/kg\\\\\\\\ (2/3)*Q=Q_v\\\\\\\\ Q=(3/2)*379=568.5 kJ/kg\\\\\\\\ C_p [T_4-T_3 ]=Q/3\\\\\\\\ 1.005*[T_4-1199]=568.5/3\\\\\\\\ T_4=1387.55 K](https://lambdageeks.com/wp-content/ql-cache/quicklatex.com-16101adc0e9d29571aa2ae5394d2b62b_l3.png)

An air standard dual cycle before compression air is at 100 kPa and 300K. During compression the volume changes from 0.07 m3 to 0.004m3. For constant pressure heat addition, the temperature varies from 1160 C to 1600C. Find the compression ratio; mean effective pressure and cut-off ratio for the cycle.

P1 = 100 kPa, T1=27 C = 300K

Compression ratio

![]()

T3 = 1160C = 1433 K, T4 = 1600 C = 1873 K

For isentropic compression process

![]()

Cut-off ratio

![Rendered by QuickLaTeX.com \\\\r_c=[T_4/T_3 ]=[1873/1433]=1.307\\\\\\\\ Also \\;\\\\\\\\ r_c=[V_4/V_3] =1.307\\\\\\\\ V_4=1.307*0.004=5.228*10^{-3} m^3](https://lambdageeks.com/wp-content/ql-cache/quicklatex.com-b809892b3aac2d862e3a5f4e08ca9735_l3.png)

For isentropic expansion process

![Rendered by QuickLaTeX.com \\\\T_5/T_4 =[V_4/V_5] ^{\\gamma-1}\\\\\\\\ (T_5/1873)=[\\frac{(5.228*10^{-3})}{0.07}]^{1.4-1}\\\\\\\\ T_5=663.48 K](https://lambdageeks.com/wp-content/ql-cache/quicklatex.com-3c2788b7142d2658ebd2be9ada56a46a_l3.png)

Total Heat Supplied

![Rendered by QuickLaTeX.com \\\\Q_s=C_v [T_3-T_2 ]+C_p [T_4-T_3 ]\\\\\\\\ Q_s=0.717*(1433-942.6)+1.005*(1873-1433)\\\\\\\\ Q_s=793.81 kJ](https://lambdageeks.com/wp-content/ql-cache/quicklatex.com-e98662763e1036e6adb2d3e4c2f5db76_l3.png)

Heat rejected

Work done is given by

![]()

Mean effective pressure for dual cycle

FAQ

Q.1) where is dual cycle used?

Ans: – Dual cycle is widely used for small propulsion engines and portable heavy duty machinery like drilling machines by companies like Cummins etc. The major reason of dual cycle being used in mobile equipments is it provides high power to mass ratio in comparison with Otto and diesel cycle.

They have wide range of application in aircraft and ships. Dual cycle engine are also called marine engine.

Q.2) what is the efficiency of dual cycle?

The efficiency of dual cycle is given by

![Rendered by QuickLaTeX.com \\eta_{dual}=1-\\frac{1}{r_k^{\\gamma -1}}[\\frac{r_pr_c^\\gamma -1}{(r_p-1)+r_p\\gamma (r_c-1)}]](https://lambdageeks.com/wp-content/ql-cache/quicklatex.com-ef5d62cb8110d7b8f13b61f35836bb06_l3.png)

Where, rp = Pressure ratio = P3/P2

rk = compression ratio = V1/V2

rc = cutoff ratio = V4 /V3

re = expansion ratio = V5/V4

When rc = 1, The cycle becomes Otto cycle

rp = 1, the cycle becomes diesel cycle.

Q.3) what are the importance of dual cycle in the diesel engine operations?

Dual fuel engine works primarily on diesel cycle. The gaseous fuel [Natural gas] is introduced into the engine’s intake system through a supercharger at higher atmospheric pressure.

During the suction stroke, the leaner air-to-fuel ratio [air-to-natural gas mixture] is drawn into the cylinder, following the Otto cycle just as used in a spark-ignited engine. A small charge of pilot fuel is injected near the Top Dead Center and similar to CI engine it ignites near the end of the compression stroke, causing the secondary gas to burn. The combustion takes place smoothly and rapidly.

In dual-fuel engine pilot fuel and secondary fuel both burn simultaneously in a compression ignition engine. After the compression of secondary fuel at the suction stroke pilot fuel is used as a source of ignition.

The operating cost of this engine is lower than that of conventional diesel engine without compromising in delivery power, high torque and transient response.

Q.4) why is the dual cycle known as a mixed cycle?

Dual fuel engine works primarily on diesel cycle. The gaseous fuel [Natural gas] is introduced into the engine’s intake system through a supercharger at higher atmospheric pressure.

During the suction stroke, the leaner air-to-fuel ratio [air-to-natural gas mixture] is drawn into the cylinder, following the Otto cycle just as used in a spark-ignited engine. A small charge of pilot fuel is injected near the Top Dead Center and similar to CI engine it ignites near the end of the compression stroke, causing the secondary gas to burn. The combustion takes place smoothly and rapidly.

In dual-fuel engine pilot fuel and secondary fuel both burn simultaneously in a compression ignition engine. After the compression of secondary fuel at the suction stroke pilot fuel is used as a source of ignition.

The operating cost of this engine is lower than that of conventional diesel engine without compromising in delivery power, high torque and transient response.

Q.5) what is cut off ratio in dual cycle?

The cut-off ratio for dual cycle is given by

rc = cutoff ratio = V4 /V3

Where, V4 = volume after partial heat addition at constant pressure

V3 = volume after partial heat addition at constant volume

Q.6) What is Dual cycle P-V and T-S diagram ?

To see the answer Click here

Q.7) Dual cycle solved example.

A C.I engine has a compression ratio of 10. The heat liberated at constant volume is 2/3 of total Heat while the remaining is liberated at constant pressure. The initial pressure and temperature is 1 bar and 27oC. Maximum cycle pressure is 40 bars. Find temperature at the end of compression and expansion. [PV1.35 = C, ϒ = 1.4]

Solution: rk = 10, P1 = 1 bar = 100 kPa, T1=27 C = 300K, P3 = P4 = 40 bar, PV1.35 = C, ϒ = 1.4

Heat input at constant volume

![Rendered by QuickLaTeX.com \\\\Q_v=C_v [T_3-T_2 ]=0.718*[1199-671]=379kJ/kg\\\\\\\\ (2/3)*Q=Q_v\\\\\\\\ Q=(3/2)*379=568.5 kJ/kg\\\\\\\\ C_p [T_4-T_3 ]=Q/3\\\\\\\\ 1.005*[T_4-1199]=568.5/3\\\\\\\\ T_4=1387.55 K](https://lambdageeks.com/wp-content/ql-cache/quicklatex.com-16101adc0e9d29571aa2ae5394d2b62b_l3.png)

An air standard dual cycle before compression air is at 100 kPa and 300K. During compression the volume changes from 0.07 m3 to 0.004m3. For constant pressure heat addition, the temperature varies from 1160 C to 1600C. Find the compression ratio; mean effective pressure and cut-off ratio for the cycle.

P1 = 100 kPa, T1=27 C = 300K

Compression ratio

![]()

T3 = 1160C = 1433 K, T4 = 1600 C = 1873 K

For isentropic compression process

![]()

Cut-off ratio

![Rendered by QuickLaTeX.com \\\\r_c=[T_4/T_3 ]=[1873/1433]=1.307\\\\\\\\ Also \\;\\\\\\\\ r_c=[V_4/V_3] =1.307\\\\\\\\ V_4=1.307*0.004=5.228*10^{-3} m^3](https://lambdageeks.com/wp-content/ql-cache/quicklatex.com-b809892b3aac2d862e3a5f4e08ca9735_l3.png)

For isentropic expansion process

![Rendered by QuickLaTeX.com \\\\T_5/T_4 =[V_4/V_5] ^{\\gamma-1}\\\\\\\\ (T_5/1873)=[\\frac{(5.228*10^{-3})}{0.07}]^{1.4-1}\\\\\\\\ T_5=663.48 K](https://lambdageeks.com/wp-content/ql-cache/quicklatex.com-3c2788b7142d2658ebd2be9ada56a46a_l3.png)

Total Heat Supplied

![Rendered by QuickLaTeX.com \\\\Q_s=C_v [T_3-T_2 ]+C_p [T_4-T_3 ]\\\\\\\\ Q_s=0.717*(1433-942.6)+1.005*(1873-1433)\\\\\\\\ Q_s=793.81 kJ](https://lambdageeks.com/wp-content/ql-cache/quicklatex.com-e98662763e1036e6adb2d3e4c2f5db76_l3.png)

Heat rejected

Work done is given by

![]()

Mean effective pressure for dual cycle

To know about Polytropic Process (click here)and Prandtl Number (Click here)

I am Hakimuddin Bawangaonwala , A Mechanical Design Engineer with Expertise in Mechanical Design and Development. I have Completed M. Tech in Design Engineering and has 2.5 years of Research Experience. Till now Published Two research papers on Hard Turning and Finite Element Analysis of Heat Treatment Fixtures. My Area of Interest is Machine Design, Strength of Material, Heat Transfer, Thermal Engineering etc. Proficient in CATIA and ANSYS Software for CAD and CAE. Apart from Research.