Wind turbine installation is a complex and intricate process that requires careful planning, attention to detail, and a deep understanding of the technical specifications involved. This comprehensive guide will take you through the step-by-step process of wind turbine installation, providing you with the necessary knowledge and tools to successfully execute this project.

Site Selection: The Foundation of Successful Wind Turbine Installation

The first and most crucial step in wind turbine installation is site selection. This involves evaluating a variety of factors, including:

-

Wind Speed: Accurate measurement of wind speed is essential for determining the viability of a site. According to the International Electrotechnical Committee (IEC), the International Energy Agency (IEA), and the International Network for Harmonised and Recognised Wind Energy Measurement (MEASNET), the minimum technical requirements for anemometers, wind vanes, and data loggers should be strictly followed. It is recommended to use individually calibrated anemometers to reduce uncertainty in predicted wind speed at a site.

-

Turbulence: Turbulence can have a significant impact on the performance and lifespan of a wind turbine. The site should be evaluated for turbulence intensity, which is the ratio of the standard deviation of the wind speed to the mean wind speed. The IEC provides guidelines for acceptable turbulence levels.

-

Accessibility: The site should be easily accessible for the transportation and installation of the wind turbine components, as well as for ongoing maintenance and servicing.

-

Proximity to Power Lines: The site should be located in close proximity to existing power lines to minimize the cost and complexity of grid connection.

By carefully evaluating these factors, you can ensure that the selected site is optimal for wind turbine installation and operation.

Turbine Specifications: Matching the Right Turbine to the Site

Wind turbines come in a wide range of sizes, from less than 100 kilowatts to several megawatts. The National Renewable Energy Laboratory (NREL) provides open-source data sets and develops multifidelity predictive modeling and simulation capabilities to assist in the selection of the appropriate turbine for a given site.

When selecting a wind turbine, consider the following factors:

- Rated Power: The rated power of the turbine should be matched to the wind resource at the site to ensure optimal energy production.

- Rotor Diameter: The rotor diameter determines the swept area of the turbine, which directly impacts the energy production.

- Tower Height: The tower height should be selected to ensure that the rotor blades are positioned in the optimal wind regime, taking into account factors such as wind shear and turbulence.

- Technical Specifications: The turbine should meet the necessary technical specifications, such as cut-in and cut-out wind speeds, operating temperature range, and grid compatibility.

By carefully considering these factors, you can ensure that the selected wind turbine is well-suited to the site and will deliver the desired energy output.

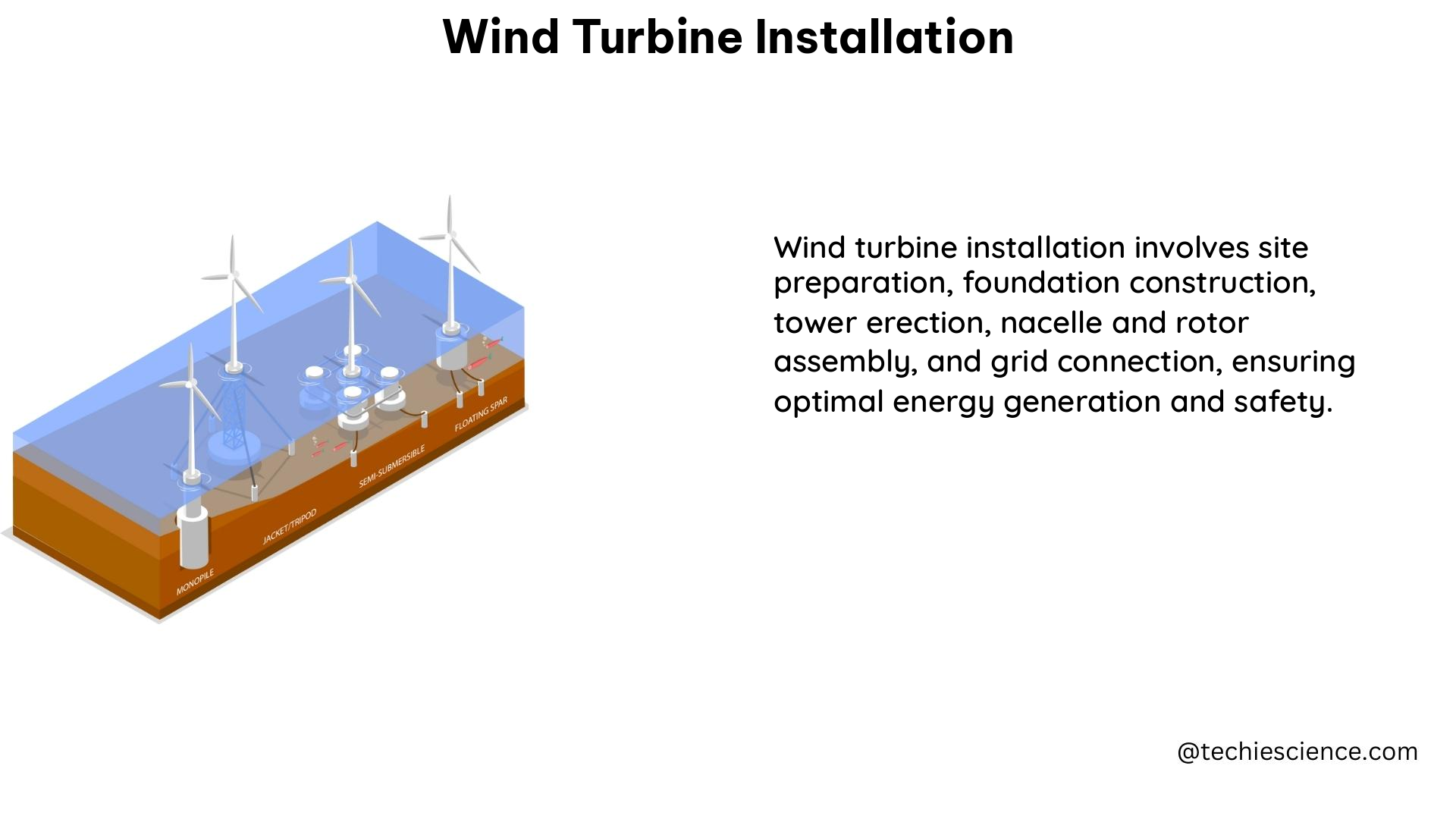

Site Preparation and Foundation Installation

Once the site has been selected and the turbine specifications have been determined, the next step is to prepare the site and install the foundation. This process involves:

- Site Clearing: The area around the turbine location should be cleared of any obstructions, such as trees, buildings, or other structures.

- Ground Leveling: The ground should be leveled to ensure a stable and level foundation for the turbine.

- Foundation Installation: The foundation for the wind turbine can be a concrete slab or a deep foundation, depending on the size and weight of the turbine. The foundation should be designed to withstand the loads and stresses imposed by the turbine during operation.

- Electrical Grid Preparation: The site should be prepared for the installation of the electrical grid, including the laying of cables and the installation of transformers and other electrical equipment.

Proper site preparation and foundation installation are critical to the long-term performance and reliability of the wind turbine.

Turbine Assembly and Installation

With the site prepared and the foundation in place, the next step is to assemble and install the wind turbine. This process involves:

- Tower Assembly: The turbine tower is typically composed of multiple sections that must be bolted together. The tower should be assembled according to the manufacturer’s instructions, ensuring that all connections are secure and properly torqued.

- Nacelle Installation: The nacelle, which houses the generator and gearbox, must be lifted and installed atop the tower. This requires the use of specialized equipment, such as a crane, to ensure safe and accurate placement.

- Rotor Blade Attachment: The rotor blades are then attached to the hub, which is mounted on the nacelle. The blades must be balanced and aligned to ensure optimal performance.

- Turbine Hoisting: Once the tower, nacelle, and rotor blades are assembled, the entire turbine must be hoisted into place using a crane or other heavy-lifting equipment.

Careful attention to detail and adherence to the manufacturer’s instructions are essential during the turbine assembly and installation process to ensure the long-term reliability and performance of the wind turbine.

Grid Connection and Commissioning

The final step in the wind turbine installation process is the connection to the electrical grid and the commissioning of the turbine. This involves:

- Transformer Installation: A transformer must be installed to step up the voltage from the turbine to the grid voltage.

- Grid Connection: The turbine must be connected to the power lines, ensuring that all electrical connections are secure and properly grounded.

- Commissioning: Once the turbine is connected to the grid, it must be commissioned to ensure that it is operating within the specified parameters. This includes testing the turbine’s control systems, monitoring its performance, and making any necessary adjustments.

Obtaining the necessary permits and approvals from local authorities is also a critical step in the grid connection and commissioning process.

By following this comprehensive guide, you can ensure that your wind turbine installation project is a success, delivering reliable and efficient energy production for years to come.

Reference:

- Ding, Y., Hwangbo, H., Eisele, O., Weinzierl, G., Lang, U., & Pechlivanoglou, G. (2017). Quantifying the effect of vortex generator installation on wind power production: An academia-industry case study. Renewable Energy, 107, 585-593.

- National Renewable Energy Laboratory. (n.d.). Wind Data and Tools. Retrieved from https://www.nrel.gov/wind/data-tools.html

- Wind Energy the Facts. (n.d.). Best Practice for Accurate Wind Speed Measurements. Retrieved from https://www.wind-energy-the-facts.org/best-practice-for-accurate-wind-speed-measurements.html

- Instructables. (2015). How to Build a Wind Turbine. Retrieved from https://www.instructables.com/id/How-to-Build-a-Wind-Turbine/

- Make:. (2013). Build Your Own Wind Turbine. Retrieved from https://makezine.com/projects/build-your-own-wind-turbine/

- AltEnergyMag. (2012). DIY Wind Turbine Projects. Retrieved from https://www.altenergymag.com/article/2012/05/diy-wind-turbine-projects/1965/

- Modular Wind Energy. (n.d.). Modular Wind Turbines. Retrieved from https://www.modularwindenergy.com/modular-wind-turbines/

- Urban Green Energy. (n.d.). Vertical-Axis Wind Turbines. Retrieved from https://www.urbangreenenergy.com/technology/vertical-axis-wind-turbines/

- Wind Energy the Facts. (n.d.). Vertical Axis Wind Turbines. Retrieved from https://www.wind-energy-the-facts.org/vertical-axis-wind-turbines/

The lambdageeks.com Core SME Team is a group of experienced subject matter experts from diverse scientific and technical fields including Physics, Chemistry, Technology,Electronics & Electrical Engineering, Automotive, Mechanical Engineering. Our team collaborates to create high-quality, well-researched articles on a wide range of science and technology topics for the lambdageeks.com website.

All Our Senior SME are having more than 7 Years of experience in the respective fields . They are either Working Industry Professionals or assocaited With different Universities. Refer Our Authors Page to get to know About our Core SMEs.