The efficiency of any device is a measure of its performance

The turbine efficiency is expressed as the ratio of useful work energy output to the input energy.

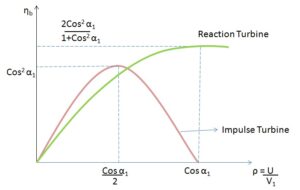

There are mainly two types of a steam turbines. One is an impulse turbine, and another is a reaction turbine. The efficiency of both turbines is different, and it depends upon its action of work.

There are many factors on which the turbine efficiency depends. It can be blade angle, guide vanes angle at the inlet to the turbine, velocity of steam, etc.

turbine efficiency formula

We can know and compare the performance of turbine with turbine efficiency

Here,

h3 – enthalpy on point 3

h4 – the enthalpy point 4 (actual turbine)

h4s – the enthalpy point 4s (isentropic turbine)

The isentropic efficiency of the turbine can give us an ideal performance of the turbine. The heat rejected to the surrounding is to be assumed as zero. The isentropic efficiency can be calculated by the ratio of actual work to ideal work.

The ideal turbine is a device that works with 100 % efficiency. It means that all the input energy is converted into useful work. This type of turbine is impossible in the real world. There are always some losses present in the turbine in the form of heat and friction.

turbine efficiency curve

the turbine efficiency curve for impulse and reaction turbine is shown below

What is stage efficiency of a turbine

The stage efficiency or gross efficiency of the turbine is related to the stages of blades.

The stage efficiency is the ratio work supplied on the blade by per kg of steam to the energy given per stage (per kg of steam)

Stage efficiency can also be expressed as the multiplication of nozzle efficiency and blade efficiency.

In an impulse turbine, there are stages of blades and nozzle set. The stage efficiency is the providing performance of stage by work done in the stages and enthalpy dropping in nozzles.

how to improve turbine efficiency

The turbine efficiency can be improved by some factors discussed below

It can be enhanced by the superior blade design, Coatings of exhaust blade and geometry

Why turbine has more efficiency than pump

The pump and turbine efficiency can be compared based on fluid handling

The pressure losses in the pumps are higher than in the turbine. This loss can be reduced by making the boundary layer thin in the turbine.

The working fluid in the turbine is expanding from the inlet. At the inlet, the static pressure and the velocity rise continuously. The rising in the kinetic energy of the fluid leads to a decrease in losses. The thin boundary layer can decrease the losses of power.

In the pump, the boundary layer thickness of fluid is more due to deceleration to raise static pressure. This increase in thickness leads to an increase in the losses in the pump.

average turbine efficiency

The average efficiency of the turbine varies between some range depending on size and stage.

The average efficiency of a single-stage turbine is 40 % whereas, the efficiency for the multi-stage turbine is 65 – 90%.

The efficiency in the multistage turbine is high due to the moderate to high pressure ratio. The steam will get expanding through various stages, which is beneficial to efficiency.

What is the ideal efficiency range for practical turbines

The ideal efficiency range of a practical turbine is dependent on various losses.

The overall plant thermal efficiency for the steam turbine is 42- 45%.

The power plant running on the superheated boiler is working with fossil fuels like coal. There are many heat losses present in a practical turbine. Due to thermal losses, the efficiency of the practical turbine is low.

turbine vs piston efficiency

The turbine and piston engine can be compared for aircraft

The piston engine is more efficient compared to the turbine due to less specific fuel consumption.

The turbine is light in weight compared to piston engines. The weight of piston engines is more due to bore, turbocharger, etc. To reduce the unbalancing in an airplane, a long nose is provided.

What is the maximum efficiency of a generator

The generator is a device that provides electrical energy at the expense of mechanical energy.

If the losses are proportional to the square of load current, then the generator’s efficiency is maximum.

The generator efficiency can be stated as the ratio of output electrical power to input mechanical power.

The efficiency of the dc generator can be maximum if the variable and constant losses are the same. The variable losses are armature losses, and the constant losses are field circuit losses and rotational losses.

I am Deepak Kumar Jani, Pursuing PhD in Mechanical- Renewable energy. I have five years of teaching and two-year research experience. My subject area of interest are thermal engineering, automobile engineering, Mechanical measurement, Engineering Drawing, Fluid mechanics etc. I have filed a patent on “Hybridization of green energy for power production”. I have published 17 research papers and two books.

I am glad to be part of Lambdageeks and would like to present some of my expertise in a simplistic way with the readers.

Apart from academics and research, I like wandering in nature, capturing nature and creating awareness about nature among people.

Also refer my You-tube Channel regarding “Invitation from Nature”