Eddy Current Brake

An eddy-current brake is one of the alternative of traditional hydraulic brake also known as an electric brake. This is a device employed to slowdown or stopover a running body by dissipating its K.E as heat and brake force is provided by an electro-magnetic force between an electromagnet and surrounding conductive material, as of eddy current induced in that for electromagnetic induction.

In other hands, friction brakes work exploiting friction between 2 material faces fixes together.

- Eddy current brake is for the substitution of hydraulic brake.

- Alternating Current created field applications has been updated.

Note: Usually, an accurate Finite Element Modelling is used to validate the eddy current analysis because of complex mathematical form.

How does an eddy current brake work?

Eddy current brake design

In these brakes, the magnetic field commonly produced by permanent-magnets or by an electro-magnet because of electro-magnet brake force may be switch off or vary as require by changing the electric current of electro-magnet windings.

The benefit of this brakes is not operated by friction, there are not any brake-surface to utilize, because of this reason this can replace the friction brake. It’s drawback is braking is proportionate to the relative speed of the brake, and has to convey force when the moving object is in motionless condition, hence in automobiles, it has to be supplemented by means of a frictional one.

Eddy currents are produced, as explained earlier when a conductor passing thru a electromagnetic field, an opposite forces will generate and will circulate inside metallic conductor.

Eddy current brake design will follow:

- This type will able to slow down an object by creating eddy-current thru creating resistance via e.m.f.

- Braking action is provided thru changing magnetic field.

- A brake force is applied by electro-magnets.

Electromagnets are widely used for this type of brakes, instead of permanent magnets, because the energy of the magnetic field can be altered, and so the braking effect as well. One key problem with eddy brakes is not having sufficient “holding” torque sometimes. Therefore, these brakes are frequently used together with standard mechanical brakes.

Eddy Current Brake Resistance

The brake force within an eddy current brake is an electro-magnetic force in-between a magnet and conductors via electro-magnetic induction.

Image credit :Chetvorno, Eddy current brake diagram, CC0 1.0

Advantage of eddy current brakes

- It’s ideal for many types of machinery because of a shortage of physical contact between parts, making this brake really low-maintenance in compare to traditional frictional one.

- The cost-effective design is also an advantage related to these brakes have made them a favorite choice among engineers.

- Eddy-current is mechanically robust in design, less wear and tear parts present.

Eddy current brake calculation

The current density of brake is as follows:

Where,

σ is conductivity, ω is angular speed, μ is permeability,

Rdrum is the radius of the drum, delta is skin depth measured by

The eddy current loss of the brakes is all used as braking forces. The eddy current loss (Pe) is in usual terms,

Where are eddy current brakes used?

These are utilized to slow high-speed rails and roller coasters, even as a competitor to frictional brakes from semi-trailer trucks to help stop brake overheating and wear-tear, to prevent powered tools fast enough if power is switch-off, and also in electrical energy meters used for electricity bill generation.

The application of Eddy current brakes

This comes with many applications; a couple of cases are as follows:

- High-Speed Trains

- It is a proven technology to slowing down a high-speed train whilst considering comfort to the passenger, minimize the jerking effect. Through the usage of the technology, commuter, as well as trains, may safely reach quicker speeds and while keeping higher safety regulations.

Take-y at the Japanese language Wikipedia / CC BY-SA

- Power Tools and Industrial Equipment

- One of the main applications of it is to get emergency switch off or slows down purposes in heavy industrial equipment and power tools. When triggered, this brakes can safely deliver a heavy machine into a fast lag-free stop.

- Exercise Equipment

- Possibly the most normal eddy current brakes could also be exploited at the fitness center.

- Eddy current brake bicycle

Image Credit: Glory Cycles from Greenville, SC , USA, Eddy Merckx Mourenx 69 Disc 105 (29756618873), CC BY 2.0

- Amusement Park Rides

- Amusement park rides are equipped eddy current brake for generating stopping power in daring sports equipment’s. This is supplying a high degree of safety; Employing this brakes quick switchover and fast speedup is possible, these are good features for Amusement Park Riding.

- This braking system is generally used after a roller coaster jump or after the over-speed. Utilizing the eddy current brake, the more speedily a roller coaster go, the quicker the brake will able to slowdown.

- Electrical energy meters:

Why do cars not have eddy current brakes?

- One core disadvantage with eddy current brakes is less “holding” torque. Therefore, eddy-current brakes are frequently employed together with standard mechanical brake.

- This too dissipates heat during breaking operation. In comparison to regenerative braking, charging the battery of the vehicle is not possible. The high speed and weight of these trains would wear out conventional brakes in no time.

Types of Eddy current Brakes

- Linear eddy-current brakes. (conductors are placed in straight-rail)

- Disk eddy-current brakes. (conductor is in a flat-disk rotor which rotate)

Linear eddy current brake

Here, magnet doesn’t touch the rail but is held in a steady little distance from the rail. (Roughly few mm only).

An advantage of this linear brake is that because every part of rail passes only through the magnetic field of the brake, compared to the disc brake where each segment of the disc physically touches through the brake, so less heat production, less noise, no wear-tear but have a higher braking power than conventional disc brakes. The eddy current brake is better option to be used for emergency braking.

Modern roller coasters utilize this kind of braking. To avert the issues posed by electricity outages, they use permanent magnets rather than electromagnets, hence not needing a power source. This use lacks the prospect of adjusting braking power as readily as with electromagnets.

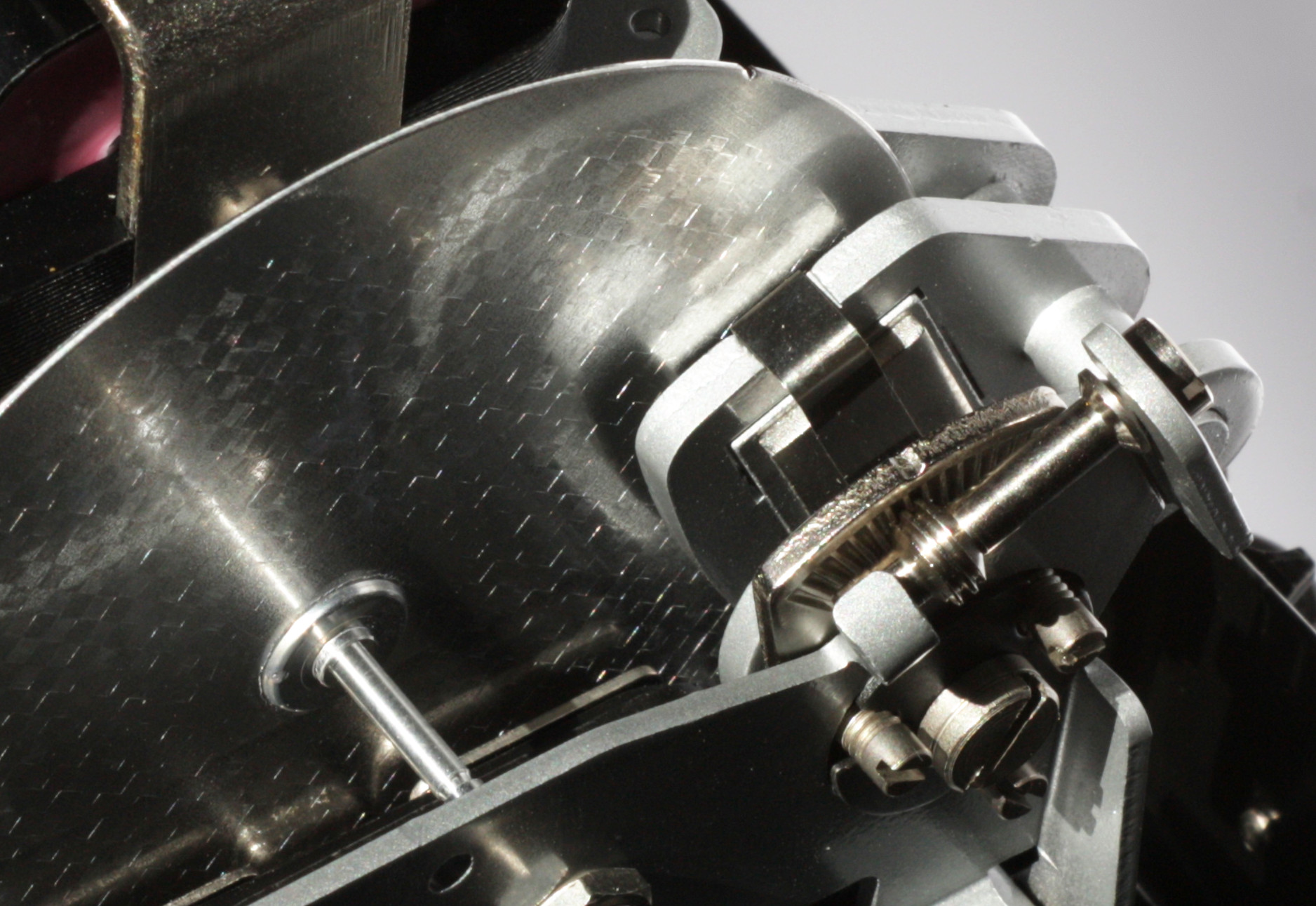

Disk eddy current brakes

A disc eddy current brake is composed of a conductive non-ferromagnetic metallic disc (rotor) attached to the axle of the wheel.

This type of brakes get heated easily than standard linear brake. These are utilized in vehicles i.e., trains, and power apparatuses like circular saw, to stop the blade instantly whenever the electricity is off.

Eddy current brake manufacturers

Some of the good eddy current brake manufacturers are

- Intamin

- Guangzhou Kingan Auto Part

- Taylor Dynamometer

- Telma

- Dynamatic etc.

To know more about Eddy current click Eddy Current Testing and Eddy Current Sensor.

Also Read:

- Golgi apparatus

- Quotient rule

- Mesosphere

- Tsunami the most devastating calamity

- How is shadow formed

- Hypertonic vs hypotonic

- What is pneumatic gripper

- Axiom and postulate

- Irrational number

- Strike and dip

I am Subrata, Ph.D. in Engineering, more specifically interested in Nuclear and Energy science related domains. I have multi-domain experience starting from Service Engineer for electronics drives and micro-controller to specialized R&D work. I have worked on various projects, including nuclear fission, fusion to solar photovoltaics, heater design, and other projects. I have a keen interest in the science domain, energy, electronics and instrumentation, and industrial automation, primarily because of the wide range of stimulating problems inherited to this field, and every day it’s changing with industrial demand. Our aim here is to exemplify these unconventional, complex science subjects in an easy and understandable to the point manner.