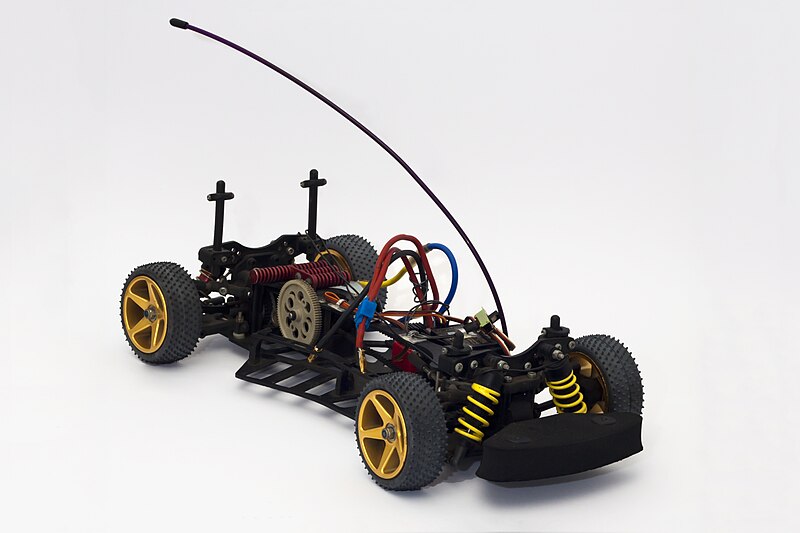

RC motor car is a remote-controlled motor car that can use either a brushed or brushless motor as its component.

The motor in the RC car is responsible for the movement of the car, and this article has discussed a Brushed vs brushless RC motor.

Brushed vs Brushless Motor RC Car

There are different benefits or drawbacks of each brushed or brushless motor, there is the comparison between both brushed vs brushless motors.

Comparison between brushed vs brushless RC motor:

| Parameters | Brushed Motor of RC car | Brushless Motor of RC car |

| Efficiency | Relatively lower efficiency From 75 to 80%. | Relatively higher efficiency from 80 to 90%. |

| Lifespan | Relatively low lifespan due to more moving components. | Relatively long lifespan, around 10,000 hours of operation. |

| Speed range | The brush and commutative limit the speed of a brushed motor. | The speed of the brushless motor is only limited by the controller’s speed. |

| Noise | Higher electrical and mechanical noises are due to high friction between brush and commutator or electrical arc. | Relatively low mechanical and electrical noises due to the absence of brushes. |

| Cost | Relatively Inexpensive. | Relatively expensive. |

| Torque | For an identical power supply, a relatively lower torque is generated due to less efficient energy conversion. | Or identical power supply high torque is generated due to high-efficiency conversion of energy in brushless motor. |

| Controller | There is no requirement for any external controller to control its speed or switching. | It required an external controller to control its speed or switching. |

| Components | It contains a brushes and commutators for collection between each other. | It doesn’t contain any brushes as its component. |

Can you put a brushless motor in a brushed RC car

A brushed motor is a type of DC motor which does not have any parts as a brush, whereas a brush motor contains a brush in contact with a commutator.

A brushless motor can be pleased in place of a brushed RC motor if the specifications or other ratings are identical.

Conversion of the motor cannot take place. Still, you can change a brushed motor with a breathless motor along with the electronic speed controller (ESC) as a brushless motor requires an external electronic speed controller for proper operation.

While replacement consider the motors operating range and current or voltage ratings as well as required operating speed, size of the motor, after considering all essential facts brushed motor can be replaced with a brushless motor, with replacing a brushed motor with a brushless motor there can we many differences due to high efficiency of brushless motor speed and torque of the motor can be increased relative to a brushed motor and there are other benefits also such as less electrical or mechanical noise, etc.

What is benefit of brushless motor in RC car

There are various benefits of using the brushless motor in an RC car:

- Easy and low-cost maintenance due to the absence of resources and fewer moving contacts.

- High torque to weight ratio means high output power generation in a relatively smaller size relative to having a brushed motor.

- There is no limitation to the speed of the motor due to brush or commutator; there is only limit to its speed is the speed of the controller. The faster the controller, the higher the speed of the motor. The highest speed range can be achieved quickly with a brushless motor because of its relatively low moving parts, resulting in relatively fewer frictional losses.

- High efficiency relative to a brushed motor at all speeds with rated load.

- Due to the absence of brushes, the brushless motor becomes more durable than a brushed rc motor.

- A Brushless motor is faster than that of a brushed motor for an identical power supply.

- Relatively low overheating problem.

- High reliability and stability due to fewer moving parts, which causes less friction, low energy losses, low mechanical or electrical losses, noise, etc.

- Relatively low electromagnetic interference.

- A brushless motor makes it easy to control the winding current for the smooth current transition between windings, resulting in a low torque ripple.

- Low operational noise.

- Relatively compact motor size rather than a brushed rc motor.

- Due to less heat and friction, spark generation is relatively low, even with the intensive workload.

- Brushless motors do not wear out as quickly as brushed motors.

Also Read:

- What is the role of transistors in flip flop circuits

- Gate equations solving

- Is the hpf s cutoff frequency always at the point of 3db attenuation

- Can the frequency spectrum of a signal be altered

- Boolean algebra simplification

- Is there a limit to how fast signals can be transmitted over a communication channel

- Fan in and fan out implications

- Does the frequency spectrum determine the bandwidth of a signal

- Is it feasible to achieve a perfect brick wall response in an hpf

- Operational amplifier op amp

I have graduated in Applied Electronics and Instrumentation Engineering. I’m a curious-minded person. I have an interest and expertise in subjects like Transducer, Industrial Instrumentation, Electronics, etc. I love to learn about scientific researches and inventions, and I believe that my knowledge in this field will contribute to my future endeavors.